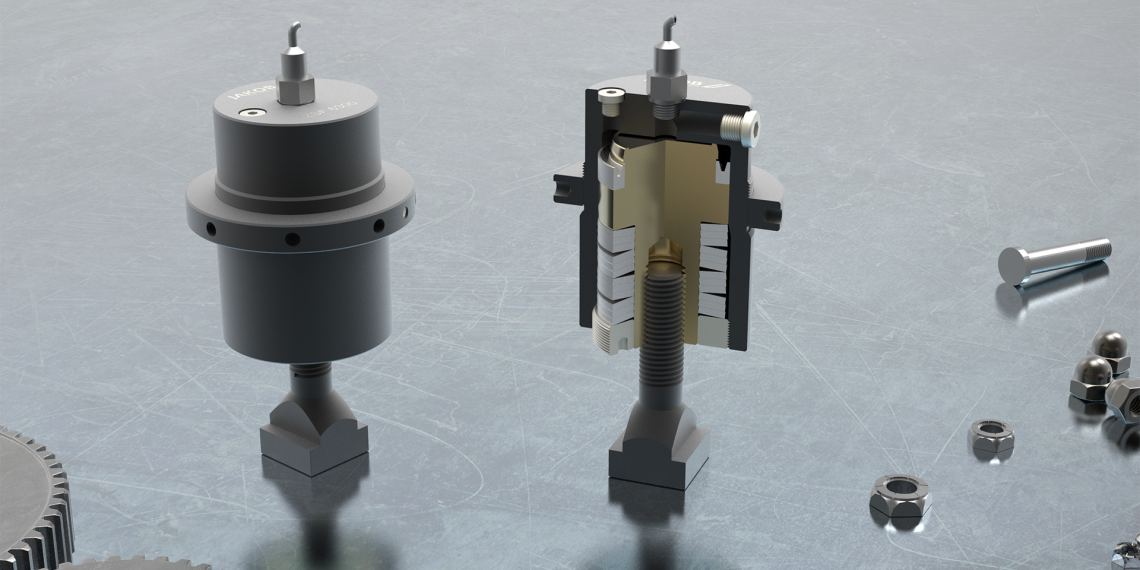

The hydromechanical spring-loaded cylinders of the ZSF series from Jakob Antriebstechnik offer robust and reliable clamping elements. These spring-loaded systems can be used wherever displaceable or movable machine parts must be temporarily clamped or locked. Other applications can be found in jig construction and for workpiece or tool clamping.

The spring-loaded systems interact mechanically-hydraulically. The clamping force is applied mechanically by a prestressed plate spring package. The hydraulics are only needed for the release stroke of the elements, whereby the tie rod or pressure pin is released. This system ensures a high level of operational safety, since the clamping force is always maintained at full height, regardless of oil pressure or leakage losses. In the operation the pressure or tension piston is alternately acted upon by the plate spring package or the hydraulic pressure. This means that the spring pack is compressed with increasing oil pressure, the spring force increases. At set pressure, the corresponding nominal clamping force is achieved as the reaction force of the plate spring package. To release the pressure or tension piston, a higher hydraulic pressure is required, which is proportional to the release stroke up to a maximum value. This means that the setting pressure is required only for the initial installation for exact force adjustment. In the actual operating cycle, the cylinders are driven either without pressure or with release pressure. For spring-loaded cylinders, a mandrel or tie rod is screwed into the threaded hole of the tensioning piston and secured (on request, in one piece or with special thread). Operation requires a hydraulic unit that should be equipped with a pressure gauge, a pressure relief valve, a switching solenoid valve and a pressure switching device.

The hydromechanical spring-loaded systems can score with many advantages. Due to the short operating times of the hydraulic unit, this system offers advantages in terms of economy. The acquisition costs are low, the reliability is increased, the application areas are diverse and the operation is very simple.