In the fight against the pandemic, air filters are on everyone’s lips. With filter material made of nonwoven fabric, they block the way back into rooms for aerosols containing viruses. But how can these devices not only protect health, but also be operated with filter material that is as environmentally friendly as possible?

Under clearly defined conditions, the bioplastic polylactide (PLA), also known as polylactic acid, is suitable for this purpose. This can be deduced from results obtained by researchers from the Zuse community in the recently completed “BioFilter” research project. The key question for this and other potential applications of biofilters is: How do the special properties of PLA affect filter performance and durability? After all, PLA can have practical disadvantages compared to its fossil-based competitors. The material tends to be brittle and it doesn’t particularly like high temperatures beyond 60 degrees Celsius. As a biogenic material, polylactic acid is also potentially more susceptible to wear and organic degradation. This can play an even greater role in the use of filters, e.g. in sewage treatment plants, than in air filters. Industrial customers, however, naturally want a durable, reliable product.

From monofilament to nonwoven

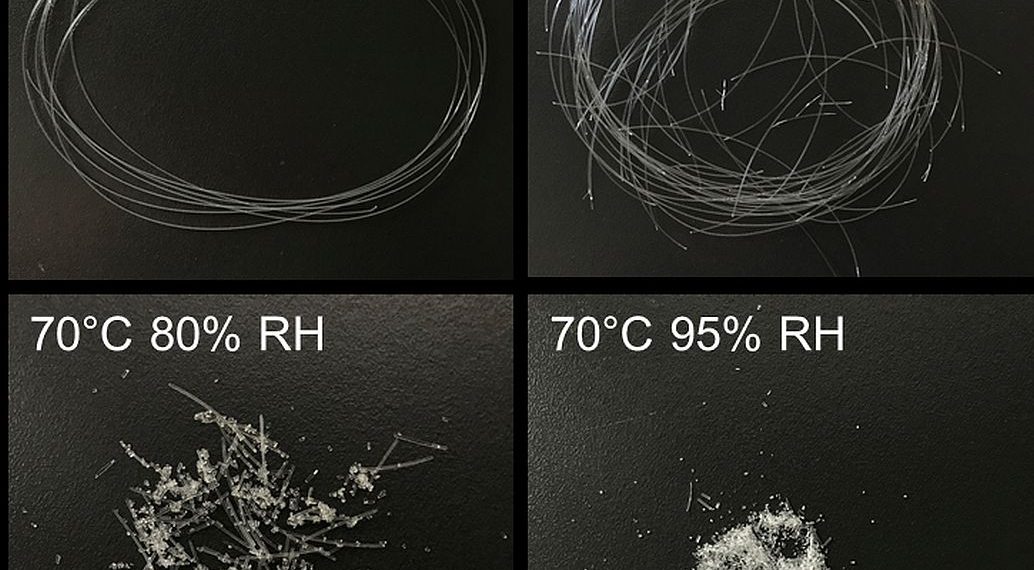

Against this background, the researchers investigated PLA properties in order to test nonwovens for biofilters on this basis. The German Textile Research Center North-West (DTNW) and the Saxon Textile Research Institute (STFI), where the nonwovens were produced, were involved. Granules from various commercially available manufacturers were used. However, the investigations did not start with nonwovens, in which the fibers are deposited close together in different layers, but with so-called monofilaments, i.e. fibers made of PLA that are comparable to threads. DTNW and STFI first carried out tests on these monofilaments, e.g. in a climate chamber for aging and durability.

As can be seen in the picture, the monofilaments became brittle after only two weeks at higher temperatures starting at 70 degrees Celsius, which the DTNW authors recently reported on in the journal Applied Polymer Materials. Under standard conditions, however, the monofilaments showed no measurable reduction in stability, even after almost three years, and the PLA nonwovens were also in no way inferior to their fossil-based counterparts in terms of filtration performance. “The focus for the use of PLA as a filter material will, in my opinion, be on applications where relatively low temperatures are present, with which PLA copes very well,” says DTNW scientist Christina Schippers.

Considering other factors besides temperature and humidity

For the researchers, however, the project, which was funded by the German Federal Ministry of Economics and Technology, was not just about the suitability of polylactide for air filters, but also for other environments, such as filtering water. In addition, the research revealed that when evaluating filter media made from biobased and biodegradable nonwovens, it is important to consider other influencing factors, such as mechanical stresses caused by air currents, in addition to temperature and humidity. “The innovative core of the project was to evaluate the possibilities and application limits of PLA nonwovens as filter media with sufficient mechanical properties and long-term stability,” says project leader Dr. Larisa Tsarkova. Like her colleagues at STFI, DTNW is involved in the Zuse Community’s Bioeconomy Cluster, in which researchers from nonprofit institutes cooperate under the guiding principle of “Researching with Nature.” “For us, the bioeconomy is a top cross-industry topic that connects numerous institutes of the Zuse community and is lived through cooperations such as with the ‘Bio-Filter’,” explains the future STFI managing director Dr. Heike Illing-Günther.

Cooperation in the bioeconomy cluster

With the results achieved from the “BioFilter” project, DTNW and STFI now want to continue working in order to be able to make deductions for clearly described areas of application for PLA nonwoven filters in the future. These possible fields of application extend far beyond room air filters and thus beyond the pandemic. For example, the water-repellent property of PLA is potentially interesting for filters in commercial kitchens for water-oil filtration or in industry for engine oils.