At IFFA from May 14 to 19, 2022 in Hall 11.1 Booth B70, the Fraunhofer Institute for Process Engineering and Packaging IVV will present solutions for the current challenges of the food industry. The intelligent, sensor-monitored cleaning lance “CleanAssist” has been developed for manual cleaning processes, enabling consistent reproducibility and quality assurance for the first time. In the field of “Food Safety”, a customizable sensor “Co-Control” for the detection of organic contamination for particularly hygiene-critical environments will be presented.

With regard to meat alternatives, the Fraunhofer IVV will demonstrate how customized food ingredients and market-ready products are created from plant-based protein sources. The holistic concepts respond to the diverse demands that Industry 4.0, climate protection and a shortage of skilled workers are placing on companies: From raw material utilization to individual solutions for safe, automated processes including hygienic design consulting and the development of sustainable packaging from recyclable packaging materials.

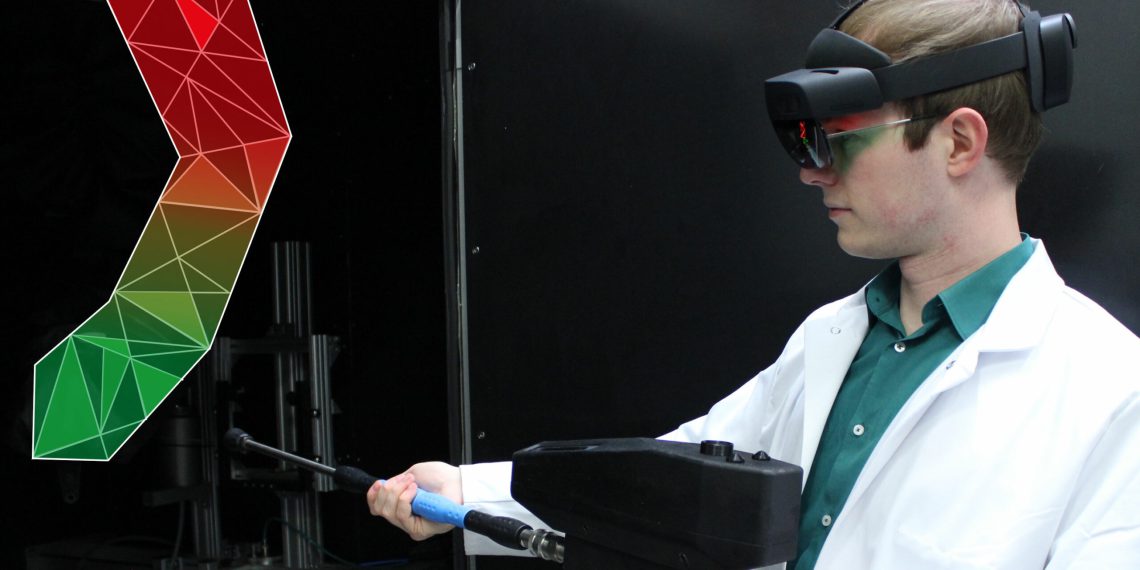

In order to be able to guarantee a safe and reproducible cleaning process for the first time even when cleaning is carried out manually, researchers at the Fraunhofer IVV have developed the first intelligent cleaning lance in a ZIM-funded joint project.

The sensors integrated into the lance enable the cleaning process to be logged. All relevant process parameters, the cleaned areas and their cleaning quality are automatically recorded. The subsequent transfer of the data to an AR device (glasses, tablet or smartphone) projects a “digital twin” into the real cleaning environment in real time. The operator of the cleaning lance is shown the cleaning success as well as the areas that still need to be cleaned. In addition, the “CleanAssist” provides support in selecting the appropriate cleaning sequence. In this way, it can be guaranteed on a locally resolved basis that all areas have been processed with the required cleaning effort.

In addition to reliable, consistent quality assurance and documentation of cleaning, the cleaning lance also enables guided optimization of cleaning runs and helps to avoid product quality-reducing errors caused by incorrect cleaning. In this way, personnel are not only supported during cleaning, but can also be trained in a targeted manner by means of special training runs.

Mobile quality assurance through imaging detection of organic contaminants

Based on the extensive know-how in the field of sensor technologies and the application-oriented design of camera-based measurement technology, the optical detection system was developed at the Fraunhofer IVV. The system is based on fluorescence analysis using UV radiation and enables the spatially resolved detection of organic contaminants on 2- and 3‑dimensional components. It can be used both as a mobile photochamber and as a customized inline system. Contaminants can thus be quantified directly in production or as an at-line or off-line solution, thus eliminating the causes of quality problems.

High-quality proteins for meat alternatives

The ongoing trend to give up meat has led to a rapid increase in demand for high-quality alternative proteins. Based on many years of experience in the production of protein ingredients and the characterization of their technological properties, the Fraunhofer IVV is working to continuously improve the sensory quality of meat alternatives. This is because very few consumers want to give up familiar dietary patterns.

The Fraunhofer IVV is meeting this high demand for meat alternatives with research into valuable protein sources from plant-based raw materials and insects. All process steps, starting from the raw material, through the development of new meat-like textures, to the hygienic production of market-ready meat alternatives, can be mapped on a laboratory and pilot scale. New product ideas are developed directly in the company’s own food pilot plant and then subjected to analytical testing. Tailor-made food ingredients with a focus on holistic raw material utilization as well as individual solutions for automated processes offer the answers to the challenges of tomorrow’s meat-processing food industry and the food trade — also and especially for medium-sized companies.