An innovative new digital printing solution for blister foils and sealed blisters for product serialization in pharmaceutical and medical device applications: Domino Printing Sciences has announced the launch of the new K600G.

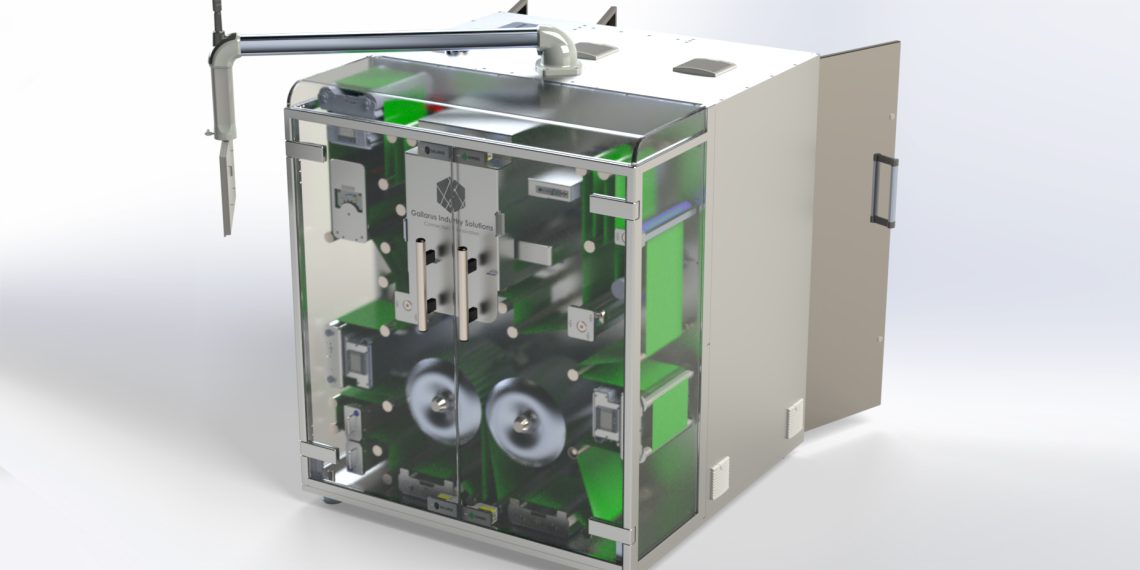

This printing solution has been developed in collaboration with innovative pharma specialist Gallarus and with input from life sciences industry expert SeaVision. It is the result of a successful team effort between digital printing market leaders and life sciences experts, and promises to ideally meet the needs of pharmaceutical manufacturers now and in the future.

“In recent years, package-level serialization has become a global requirement in the pharmaceutical industry. It is likely that serialization of individual yards of a blister pack will become the new standard in the future to further enhance patient safety and reduce medical errors. The K600G is designed to provide manufacturers with an on-site variable data printing solution that includes item-level coding to meet these future needs.”

— Craig Stobie, Director of Global Sector Development at Domino

Using digital printing technology to customize product packaging within the manufacturing chain reduces reliance on external packaging suppliers. This allows pharmaceutical manufacturers to respond more flexibly to regulatory changes or product labeling requirements.

The product offers customized options for different installation types, including offline, nearline, top-of-line and single blister coding for direct printing on formed blister packs, as well as an integrated inline version tailored entirely to the needs of machine manufacturers (OEMs).

“Digital printing and flexible supply chains are now playing a much bigger role in pharmaceutical manufacturing — so the K600G is a necessary investment to keep pace with future legislation and market trends,” explains Volker Watzke, EU Medical Devices Sector Manager at Domino.

“As Domino customers, pharmaceutical manufacturers also benefit from our experts who are always happy to support them in implementing global requirements. We want to ensure that our customers are always in control of their production lines,” Watzke continued.

“In pharmaceutical production, code quality and readability are critical. Given the cost of unplanned downtime, it is also essential that machines are always operating at optimum performance. The new development has taken into account this necessary level of reliability and longevity with regard to automated cleaning systems to reduce operator intervention and keep the system running at optimal performance,” explains Bart Vansteenkiste, Global Sector Manager — Life-Sciences at Domino.

To achieve maximum efficiency, the system can also be supplied with unique software — based on artificial intelligence — that collects, analyzes and learns from operational data to provide intelligent manufacturing solutions.

As a result, it can print at speeds of up to 75 meters per minute. Print widths range from a single print module with a print width of 108 mm to seven dual print modules with a total width of 782 mm. With precise printhead alignment and image stitching from the intelligent i‑Tech StitchLink micromotor, seamless printing across the entire web width is achieved.