Autonomous mobile robots that work safely and intuitively with humans are not only an important building block of Industry 4.0. In future space missions, they are expected to support infrastructure construction on foreign planets. In the now completed transfer project TransFIT, the German Research Center for Artificial Intelligence (DFKI), the University of Bremen and Siemens AG developed the robotic capabilities necessary for the autonomous and collaborative execution of complex assembly work. The project was funded through the German Aerospace Center e.V. (DLR) by the German Federal Ministry of Economics and Climate Protection (BMWK).

To protect astronauts from adverse environmental conditions and to enable them to stay on alien celestial bodies for longer periods of time, it is essential to build up infrastructure. Autonomous mobile robots are predestined for this demanding work, as they can perform work that is potentially dangerous or physically demanding for humans, either alone or as part of a robotic team. However, the systems reach their limits where human intellect, dexterity and creativity are required.

At the conclusion of the TransFIT project launched in July 2017, the cooperation partners from the Robotics Innovation Center of the DFKI, the Robotics Working Group of the University of Bremen and Siemens AG presented innovative technologies that not only strengthen the autonomous capabilities of the robots through artificial intelligence (AI) methods, but also enable situationally appropriate and intuitive support by humans. In addition, the partners demonstrated the high transfer potential of the solutions developed by setting up a flexible assembly cell for industrial production. In addition, a software framework developed specifically for autonomous production, which plans processes depending on system capabilities, was incorporated into the space scenario.

“Future space missions will increasingly rely on Artificial Intelligence methods and the combination of human and robotic capabilities. With the completion of the TransFIT project, which is a significant part of the DFKI Space Roadmap, we have succeeded in laying important foundations for cooperative infrastructure development in space and demonstrating the transferability of the developed technologies into the industrial context. In perspective, both industries will benefit greatly from the use of autonomous robots that can work in teams with humans.”

- Prof. Dr. Dr. h.c. Frank Kirchner

Flexible human-robot collaboration for infrastructure construction in space

In the extraterrestrial construction of stationary camps, shelters or facilities for resource extraction, robots have to cope with tasks of varying complexity. This also requires collaboration with astronauts. TransFIT therefore focused on the implementation of a cooperation scenario in which a human and a humanoid robot jointly perform an assembly task. They are supported by a person who can control the robot from a greater distance, for example from the station in orbit or from the lander, with the aid of an exoskeleton.

The cooperation partners interact to varying degrees according to the concept of “sliding autonomy”, from complete autonomy to autonomy with “operator in the loop” and teleoperation with partially autonomous functions to pure teleoperation. To realize this switch between autonomous work, cooperation and teleoperation, the project partners developed easy-to-use control software that allows rapid adaptability of the robot’s behavior on site and during the mission. In this way, even unforeseen assembly tasks such as unscheduled repairs can be performed flexibly by the robot in cooperation with the astronaut instead of autonomously.

Learning assistant robot for complex assembly work and teleoperation

As a robotic test platform, DFKI researchers built the humanoid RH5 Manus, an assistance robot developed for use in a human environment and featuring a hybrid serial-parallel design. Thanks to its innovative adaptive grasping system, which features tactile sensors, near-field recognition and a local microcontroller for biologically inspired grasping reflexes, the robot is capable of performing complex grasping movements. Machine learning-based environmental perception methods such as object recognition and grasp pose determination enable it not only to grasp and hold components, but also to cooperate directly with the astronaut.

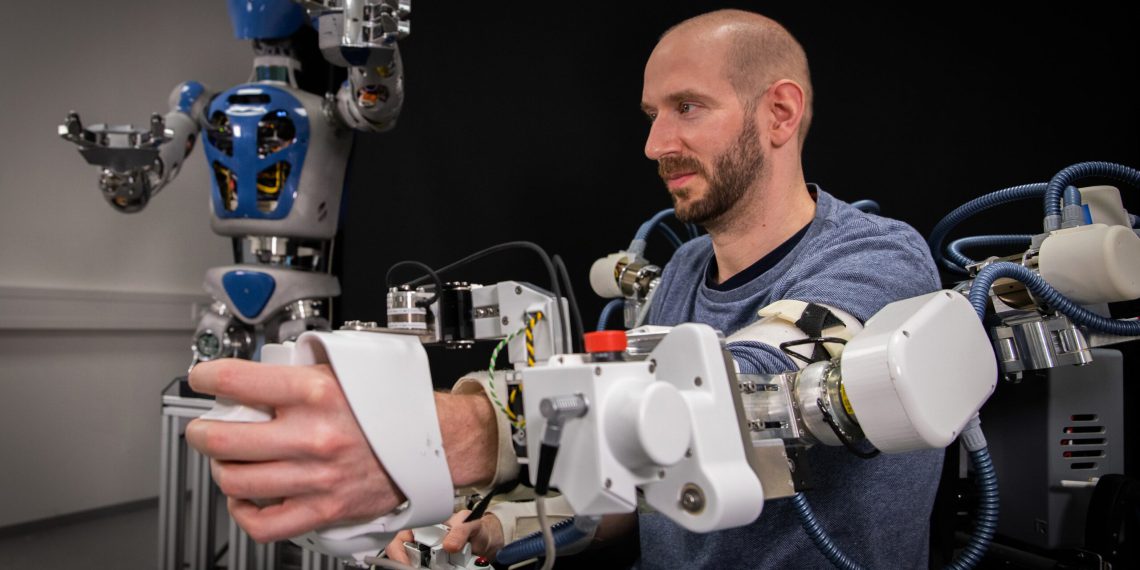

In addition, RH5 can be remotely controlled with the help of an active exoskeleton developed at the Robotics Innovation Center and optimized for teleoperation. However, the goal of the collaboration is not only the division of tasks, but also that the robot learns from the interaction with humans in order to act more and more autonomously and to be able to adapt to changing requirements. In extraterrestrial missions, for example, it must be borne in mind that the system cannot be repaired at all or at any time. If, for example, the robot is restricted in its movement because one of its joints no longer functions properly, it can adapt its behavior to take this restriction into account thanks to the technologies developed in TransFIT.

Improved teamwork thanks to intuitive interaction options

For the most intuitive collaboration possible between humans and robots, the interaction partners are able to communicate via speech using predefined commands. In addition, the robot can be controlled by simple gestures that are recognized with the help of a sensor suit worn by the astronaut or the astronaut.

The project partners are also using the human electroencephalogram (EEG) to improve the interaction: First, they developed methods to determine the cognitive load of the interacting person from the measurement data, which can be used to provide support as needed. On the other hand, in the event of an erroneous action by the robot, a negative feedback signal can be obtained from the EEG, the so-called error potential. This enables the system to continuously improve its behavior and relieves the human, who does not have to consciously provide the feedback to the robot.

Transfer of space technologies to the context of Industry 4.0

In addition to implementing the extraterrestrial cooperation scenario, TransFIT aimed to transfer the developed technologies to terrestrial applications, specifically to industrial manufacturing and production. Here, the increasing number of variants of the products to be manufactured and the ever shorter product life cycles are leading to ever smaller batch sizes. A circumstance that makes the use of classic automation paradigms almost impossible, even in assembly, which is largely dependent on manual work. Against this background, the project partners, under the leadership of Siemens AG, developed a highly flexible and cooperative assembly cell for the production of complex assemblies.

The cell, which has two robotic arms, is capable of implementing abstract task specifications autonomously and in collaboration with a human worker. To achieve this, object recognition, grasp pose determination and intuitive human-machine interaction technologies were transferred from the space scenario to the industrial context. In addition, a skill-based framework developed specifically for autonomous manufacturing enables hierarchical modeling and orchestration of sequences in the manufacturing process based on semantic product descriptions and required system capabilities. This framework has in turn been successfully transferred to human-robot collaboration in space to assign the actions required for a task to the actors and to plan the sequence of actions.