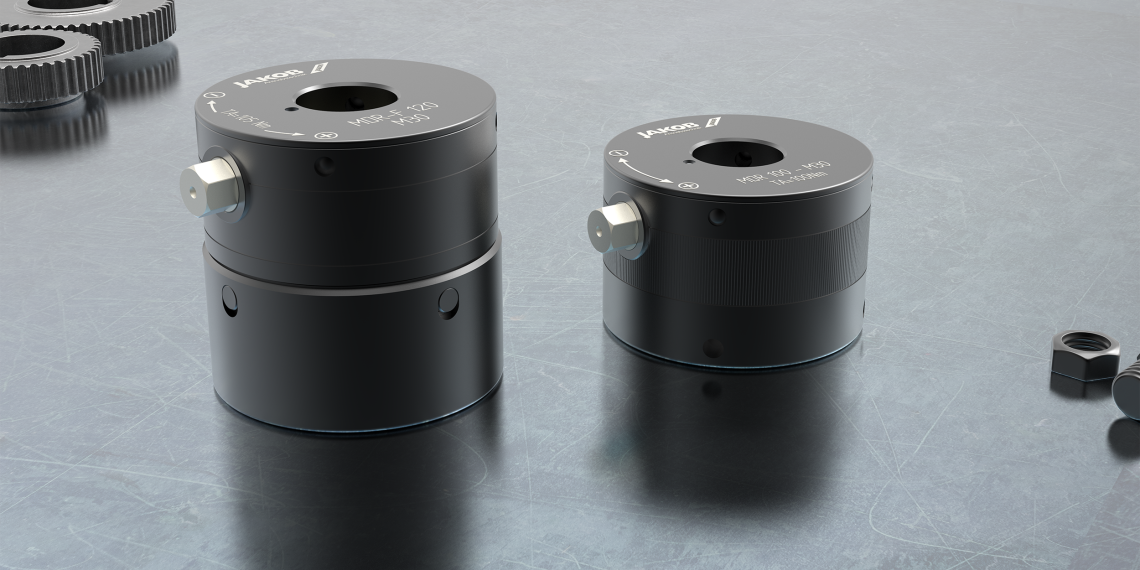

With the MDR series, Jakob Antriebstechnik presents a new universally applicable power clamping nut with a laterally arranged operating hexagon. The MDR series supplements the two types of clamping nut MCA and MDA, which have proven themselves over many years in a wide range of applications. The main design feature of the MDR clamping nut is a special crown-gear transmission with a right-angled deflection of the rotation for multiplying the tightening torque. This ensures high clamping forces with maximum operating safety with the simplest manual operation. For the thread size M30, for example, the normally required heavy duty SW46 key is replaced by the SW14 operating hexagon, thus permitting a much more comfortable work.

The connection thread allows a very flexible application with different clamping heights or tool thicknesses in combination with variable T‑slot screws or clamping bolts. In addition to the robust material design, the compact dimensions and especially the very low overall heights are to be emphasized. This also makes it possible to use with extremely restricted installation conditions. The MDR clamping nut is maintenance-free under normal operating conditions and can be used in special versions up to 400 ° C. As an option, the clamping nut can be supplied as an MDR‑F variant with an additional plate spring for the clamping stroke compensation. The spring package, integrated into an additional housing part, ensures that the clamping nut is re-adjusted with little change in the clamping length without a substantial tension force drop. This additionally increases operational safety, for example when clamping pressing tools. By means of a clamping stroke indicator (housing gap), a visual tension force control is made possible. For the time being, a size with a nominal clamping force of 120 kN (12to) and thread sizes from M16 to M30 is available.