There are very high hygiene requirements in operating rooms. Not only for personnel or ventilation and air conditioning. They also apply to the equipment used there. Operating room luminaires, for example, have to meet strict specifications. Under these special conditions, Merkle & Partner developed an internal cooling concept for an OR LED luminaire together with a luminaire manufacturer on the basis of a flow-oriented simulation calculation.

In principle, it would be a simple matter to give a product such as a luminaire more surface area in order to increase heat exchange with the environment. However, ribbed surfaces, for example, are not allowed on luminaires used in operating rooms because, among other things, uncontrollable dust formation must be avoided. The pure, smooth stainless steel surfaces of the luminaire must also not emit heat or generate air currents to the outside. Since the dimensions of the luminaire body cannot be oversized either, a new solution had to be found for an internal cooling concept; based on simulation using computational fluid dynamics.

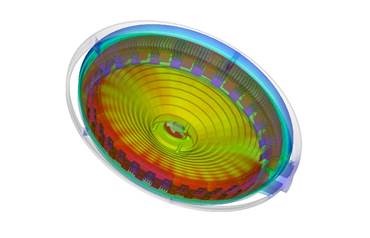

Here, the luminaire including all components as well as their properties are mapped in a simulation in order to work out a sensible cooling concept. Not only is the air circulation inside the luminaire visualized realistically, but temperature differences and changes with changing geometries or ventilation rates are also reproduced.

Here, the luminaire including all components as well as their properties are mapped in a simulation in order to work out a sensible cooling concept. Not only is the air circulation inside the luminaire visualized realistically, but temperature differences and changes with changing geometries or ventilation rates are also reproduced.

To ensure that the air is not only moved but also directed to the heat sources in a targeted manner, the necessary geometry of the luminaire’s internal structure was optimized by means of a flow calculation. The placement of components for optimal heat distribution within the luminaire was also optimally designed. The surgical luminaire thus offers an internal cooling concept that is so well designed that the luminaire meets all the requirements for use in the operating room.

“Economically, in terms of time, but also functionally, the design using computational fluid dynamics (CFD) offers the optimal solution. Digital test models can be used to identify sensible, but also less sensible, paths at an early stage and to develop innovative cooling concepts. It is no longer just a question of the time savings offered by simulation calculations. Rather, digital concepts can be developed that perhaps would not have been discovered via real trials.”

- Stefan Merkle, Managing Director of Merkle & Partner GbR