One of the main drivers of climate change is carbon dioxide — emissions must therefore be reduced in the future. Fraunhofer researchers are showing one possible way to reduce carbon dioxide emissions: They are using the greenhouse gas as a raw material, for example for plastics. To do this, they first produce methanol and formic acid from carbon dioxide, which they convert via microorganisms into building blocks for polymers and the like.

When fossil raw materials are burned, more carbon dioxide is released into the air. In the meantime, the concentration of carbon dioxide in the earth’s atmosphere has already risen to around 400 parts per million (ppm) — equivalent to 0.04 percent. By comparison, until the middle of the 19th century, this value was still in the range of 280 ppm. The high level of carbon dioxide is having a significant impact on the climate. Since January 1, 2021, carbon dioxide emissions from the combustion of fossil fuels have therefore been priced — manufacturing companies must therefore pay for their emissions. Many companies are therefore looking for new ways. How can the costs associated with pricing carbon dioxide emissions be reduced? How can emissions be reduced through biointelligent processes?

Catalytic chemistry and biotechnology — profitably combined

Researchers are currently developing approaches to this in the EVOBIO and ShaPID projects at the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB. They are working on both projects in collaboration with several Fraunhofer institutes.

“We are using carbon dioxide as a source of raw materials. To do this, we are pursuing two approaches: First, heterogeneous chemical catalysis, in which we convert the carbon dioxide to methanol using a catalyst. Second, electrochemistry, which we use to produce formic acid from the carbon dioxide.”

- Dr. Jonathan Fabarius, topic area leader for microbial catalysis

The special feature, however, does not lie solely in this carbon dioxide-based methanol and formic acid production, but in the combination with biotechnology, or more precisely with fermentations by microorganisms. In simpler terms, the researchers first produce methanol and formic acid from the climate-damaging waste product carbon dioxide. In turn, they use these as “feed” for microorganisms, which produce further products from them. One example of such a product is organic acids, which are used as building blocks for polymers — carbon dioxide-based plastics could be produced in this way. Amino acids can also be produced in this way, for example as food supplements or animal feed.

The novel approach offers numerous advantages. “We can realize entirely new products, but also improve the carbon dioxide footprint of classic products,” Fabarius specifies. While conventional chemical processes require a lot of energy and sometimes toxic solvents, products can be produced with microorganisms under milder and more energy-efficient conditions — after all, the microbes grow in more environmentally friendly aqueous solutions.

“Metabolic engineering” makes it possible

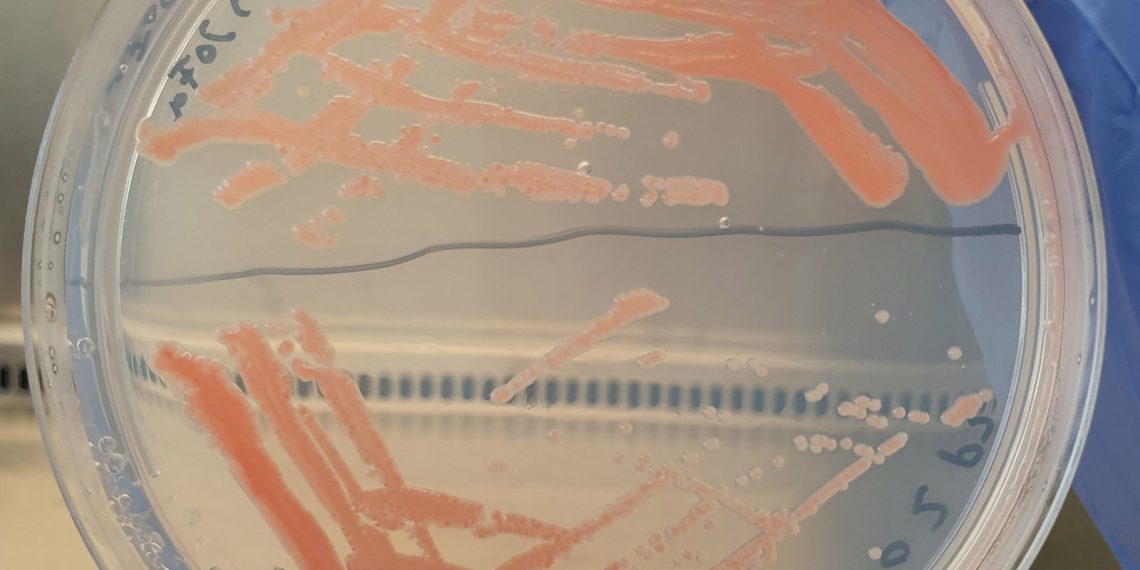

The research team uses not only native methylotrophic bacteria — i.e. those that naturally metabolize methanol — but also yeasts that cannot actually metabolize methanol. The researchers also keep a constant eye on whether new interesting organisms are discovered and check them for their suitability as “cell factories”. But how do these microorganisms actually make the products? And how can you influence what they produce? “In principle, we use the microorganism’s metabolism to control product manufacture,” Fabarius explains. “To do this, we introduce genes into the microbes that provide the blueprint for certain enzymes — this is also known as metabolic engineering.”

The enzymes that are then produced in the microorganism in turn catalyze the production of a specific product. In contrast, the researchers specifically switch off genes that could negatively influence this production. “By varying the genes that are introduced, we can produce a wide range of products,” Fabarius is pleased to report.

The research team is working on the entire manufacturing chain: starting with the microorganisms, to the gene modifications, to the upscaling of production. While some manufacturing processes are still at the laboratory stage, other products are already being produced in the first bioreactors with a capacity of ten liters. As far as the industrial application of such processes is concerned, Fabarius sees this more in the medium to long term — ten years is a realistic time horizon, he says. However, the pressure on industry to establish new processes is increasing.