The development of technology for large-scale offshore production of environmentally friendly hydrogen is being strongly pursued by Emerson. The company is developing software and systems for the safe and efficient operation of the world’s first offshore production process for environmentally friendly hydrogen on an operational gas production facility.

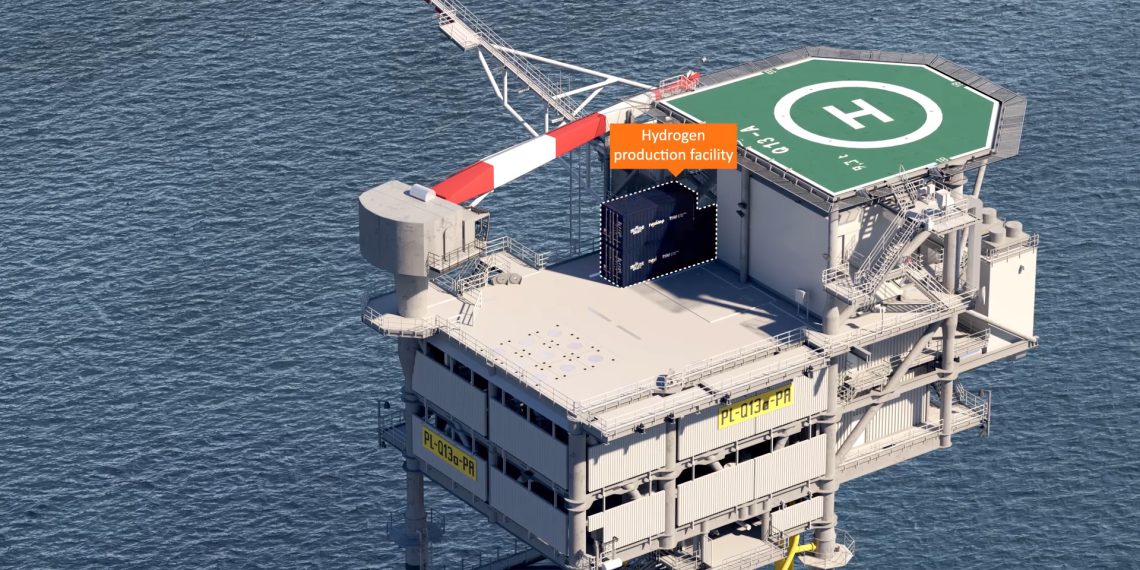

The PosHYdon project is a pilot facility to validate the integration of offshore wind energy and offshore natural gas and hydrogen production at sea in the context of renewable energy production from an environmentally friendly energy source. The project will be carried out on the Q13a‑A drilling rig operated by Neptune Energy in the Dutch North Sea. Insights will be gained into the efficiency of electrolysers supplied with variable energy and with regard to the installation and maintenance costs of a plant for the production of environmentally friendly hydrogen on an offshore platform.

Green electricity is used to simulate the fluctuating energy supply from wind turbines and to power the production process. Seawater is converted into demineralized water and hydrogen is then produced safely using electrolysis. The hydrogen is then mixed with natural gas, transported to the coast via the existing gas pipeline and injected into the national gas distribution network. The 1‑MW electrolyzer is expected to produce up to three tons of hydrogen per week.

“Hydrogen is considered the ‘energy carrier of the future,’ but meeting ambitious decarbonization and net-zero emissions targets requires expanding production capacity and accelerating the transition to sustainable energy production using hydrogen. As part of the PosHYdon project, we hope to work with consortium partners to pave the way for large-scale offshore production of environmentally friendly hydrogen and make a significant contribution to the energy transition.”

- Mark Bulanda, Executive President

Desalination and electrolyzer plants, as well as gas mixing and peripheral plant components, are controlled by Emerson’s DeltaV™ process control system, DeltaV safety-related system instrumentation and DeltaV Live Operator Interface software. By addressing specific application challenges, including variable supplies of desalinated water and power, the DeltaV software and systems provide increased safety, process availability and operational efficiency. The Emerson solution ensures that existing natural gas operations are not impacted and that the blended gas meets required specifications. Integration with existing offshore systems and communication with onshore operations optimizes visibility into the process and prevents unforeseen issues.

“The project provides a unique opportunity to develop steps needed for safe, large-scale green hydrogen production offshore,” Bulanda said. “Emerson’s experience in hydrogen value chain, wind energy and regarding the offshore energy industry will contribute to successful project implementation, and our proven technology will ensure safe and efficient operation in this novel application.”

The project was developed by consortium partners Nexstep, TNO, Neptune Energy, Gasunie, Noordgastransport, NOGAT, DEME Offshore, TAQA, Eneco, Nel Hydrogen, InVesta, Hatenboer, Iv-Offshore & Energy and Emerson. The project received a €3.6 million grant from the Netherlands Enterprise Agency (RVO) under its Demonstration Energy and Climate Innovation program, which invests in renewable energy development, including hydrogen pilot projects.