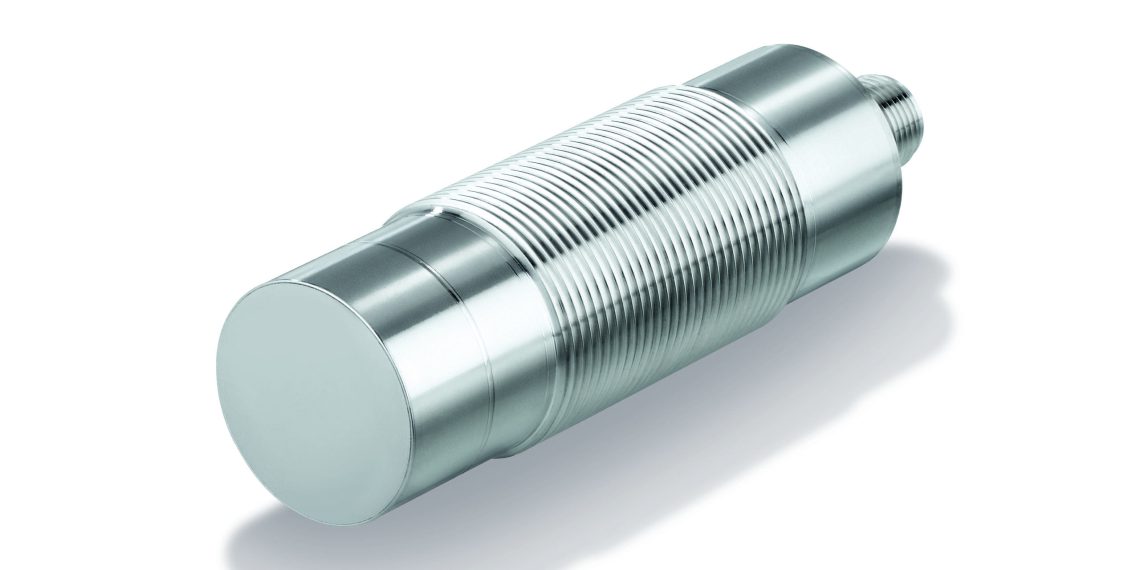

Ultrasonic sensors can be used in a wide variety of applications. The new all-metal sensors from ifm are extremely robust, have a housing made of V4A stainless steel and can therefore also be used in adverse environmental conditions.

Ultrasonic sensors are based on the time-of-flight measurement of a sound signal emitted by the sensor. One advantage of this distance measurement is that the measurement result is not affected by the material properties. Even shiny, colored or structured surfaces do not influence the measurement — even optically transparent objects can be reliably detected.

Level measurement in tanks or silos is one of the typical applications. It does not matter whether liquids or bulk solids are involved — the measurement is reliable and precise. In such applications, aggressive media and corresponding vapors pose a particular challenge for many conventional sensors. This is not the case with the new ultrasonic all-metal sensor from ifm, which has a continuous housing made of resistant V4A stainless steel. This makes the sensor more resistant to external influences and increases its service life.

The new all-metal sensor is available in different versions with ranges up to 2,500 mm. An IO-Link interface is included as standard. This allows the continuously measured distance values to be transmitted digitally and without interference, and the status of the sensor to be permanently monitored. As with all ifm IO-Link ultrasonic sensors, the sensor also provides information on the echo quality of the sensor, which additionally simplifies the adjustment of the sensor via IO-Link.