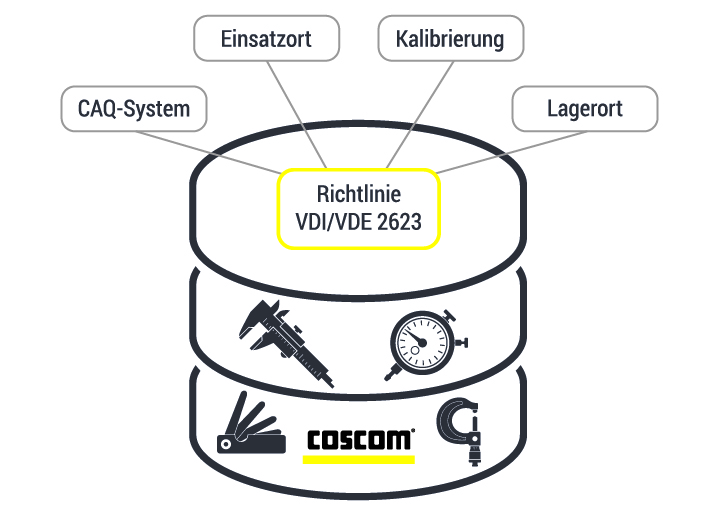

Today, digital data exchange between departments makes a significant contribution to accelerating and safeguarding work processes in a manufacturing company. COSCOM is expanding its ECO system in the area of resource management to include a standardized data exchange option to CAQ systems that complies with VDI Guideline 2623. This allows new data networking strategies to be implemented within the value-added process that are more reliable and faster.

Extended Shopfloor Platform

COSCOM, an IT platform specialist in machining manufacturing, considers measuring and testing equipment to be operating equipment in the machining process in the same way as, for example, milling and turning tools. Therefore, measuring and testing equipment must also be available at the appropriate points from the beginning of a production order. However, conventional tool management systems often consider only the CAD/CAM environment or tool presetting to be relevant with regard to data networking. The COSCOM ECO system, on the other hand, considers the complete provision of operating resources, which means that the quality assurance processes in production are also included. Therefore, it was the logical consequence to integrate the operational QA systems with a standardized data interface into the COSCOM store floor platform so that data exchange can function smoothly and, above all, in a standardized manner.

Facilitated data exchange in gauge management

In order not to generate time-consuming, individual solutions in the companies, it was important to the company’s development department to establish a generally valid standard. The new guideline VDI/VDE 2623 facilitates data exchange in gauge management by defining a uniform data format. Without this standard data format, the required data from different systems arrive in the customer’s system in a wide variety of formats, thus causing the often time-consuming and error-prone individual customer solutions.

The VDI has therefore defined a standard format for the exchange of data in gauge management in Guideline 2623. According to this guideline, the Calibration Data Exchange data format (CDE data format) must be used. This means that in the future it will also be possible to exchange test equipment data between different applications and databases using Internet-based technologies. With the application of this guideline, a reliable and fast exchange of test equipment data between different systems, such as departments, companies or plants, is guaranteed. The requirement of the VDI/VDE guideline 2623 has now been established in the system in the form of a standard interface.

COSCOM standard interface integrates QA systems

With this new measurement and test equipment interface, QA systems can now also be directly integrated via their test plan as demand generators for COSCOM resource scheduling. The availability at a planned point in time, the current storage location as well as the calibration due dates of measuring and test equipment are thus guaranteed and essential factors of a successful provisioning process.

The extension of the system according to guideline 2623 has already proven itself in practice at the beginning. Several project implementations with different QA system partners have already been successfully realized.