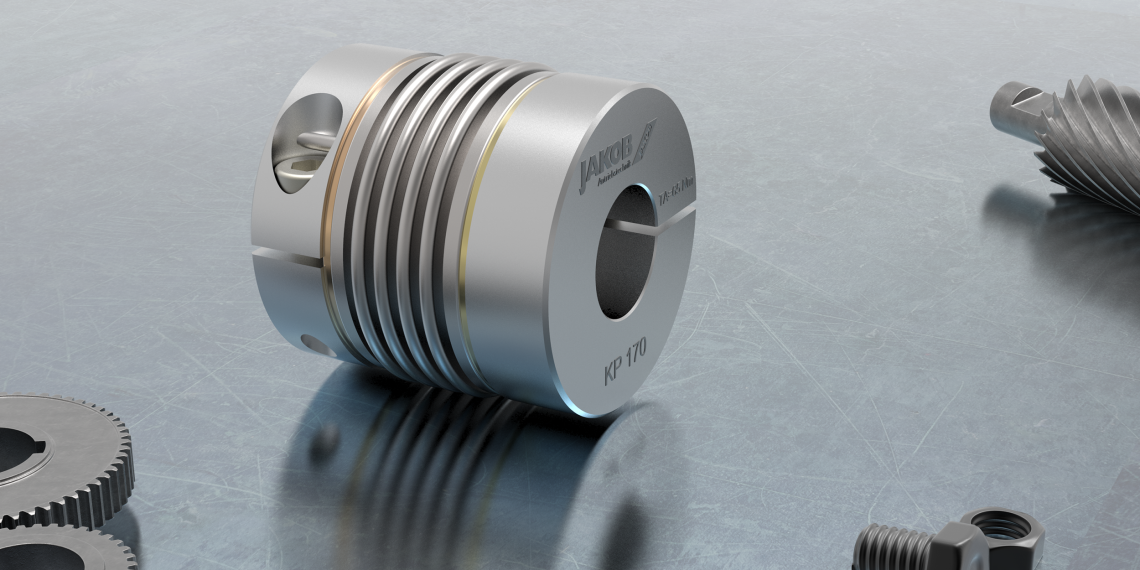

The coupling series KP with 4‑corrugated bellows and two radial clamping hubs, is a version with shorter overall length in the Jakob metal bellows coupling range. This makes it particularly suitable for applications with minimal shaft spacing and limited installation conditions. In addition, the very high torsional rigidity values and the easy-to-install clamping hub design are worth mentioning. A low moment of inertia and good values for the permissible shaft misalignments and restoring forces complete the positive picture.

The multi-layer, made of certified stainless steel, metal bellows is characterized on the one hand by its high torsional rigidity and on the other by the compensation of axial, radial and lateral shaft offsets. Due to the shortened design and the resulting weight savings, there are other advantages such as lower moments of inertia.

The clamping hub is made of high-strength aluminum to achieve the lowest possible moment of inertia. The hubs are equipped with the innovative and service-friendly Easy-Clamp-System. It guarantees a simple, with enough fitting tolerance provided postponement. A single, radially accessible screw per hub provides the for torque transmission necessary preload force. Thanks to this simple, but very reliable connection, the couplings can be mounted in just a few easy steps, even in difficult installation conditions. The bellows-hub connection is made by the optimal and backlash-free brass-wire press-fit method. In contrast to adhesive joints, this joining process is absolutely unlimited for critical operating conditions (-40 ° C to + 200 ° C, chemicals) and the transmission torque of each individual bellows layer is safely introduced into the hub.

The KP series is available for nominal torques from 25 to 900 Nm with bore diameters from 10 to 75 mm.