Collaboration between ABB and Werum IT Solutions on Shop Floor Integration reduces engineering, validation and testing time associated with biotech production.

Designed for established pharmaceutical manufacturing plants with existing machinery, the new software solution called Shop Floor Integration Version 2.0 allows for the creation of a digital twin of the existing system prior to installation. This reduces engineering, validation and testing time and minimizes the plant’s downtime. Using this new solution, engineers save between 40% and 70% of the time spent on integrating systems when compared to existing solutions.

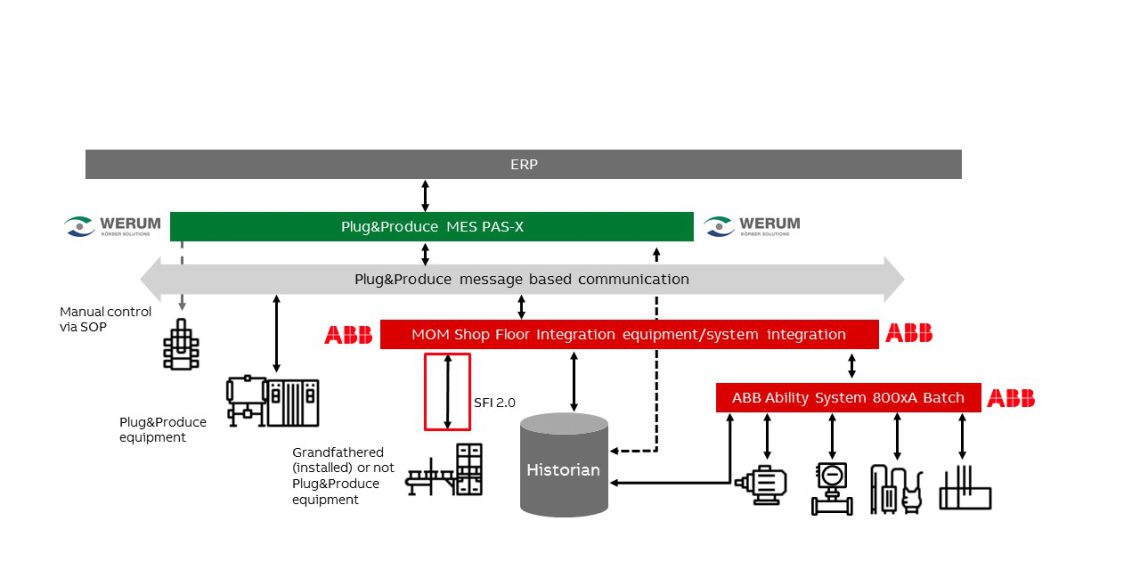

The Shop Floor Integration interface connects Werum’s PAS‑X manufacturing execution system (MES) to existing shop floor equipment. This digital solution prevents production bottlenecks and reduces cycle times so as to lower inventories, free up capacity and increase efficiency.

The company together with Werum has developed a message-based communications system that sends and receives instruction between the MES and the production equipment. This provides regular synchronization between the systems and communicates data such as quality, setpoint and consumption.

Two pharmaceutical companies are early adopters of ABB’s Shop Floor Integration product. GE Healthcare runs it as a new manufacturing installation and another large company is implementing Shop Floor Integration on an existing plant. GE Healthcare’s site in Uppsala, Sweden, is the first in the world to use ABB’s message-based communications system to connect the MES to its DCS (Distributed Control System).

The historical route for integration between manufacturing systems was both labor-intensive and multi-staged. The company has cut down the often lengthy process needed to define OPC tags, define interface handshakes, states and logic and replaced these with a simple, efficient and qualified interface needing just a few steps – defining the message, defining PAS‑X and Master Batch Record interaction and steps, and finishing with defining DCS and Batch interactions and steps. This reduces the possibilities for malfunctioning and makes it simpler to program, with less machine-operator interaction during the manufacturing process.

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more