From May 2 to 5, the pipe bending machine manufacturer Schwarze-Robitec will present its high-performance technologies for the offshore industry at the Offshore Technology Conference (OTC) in Houston, Texas. For decades, renowned companies in the industry have relied on the “made in Germany” label: the machines are designed to withstand heavy stresses in continuous use — while delivering precise and fast-fitting pipes.

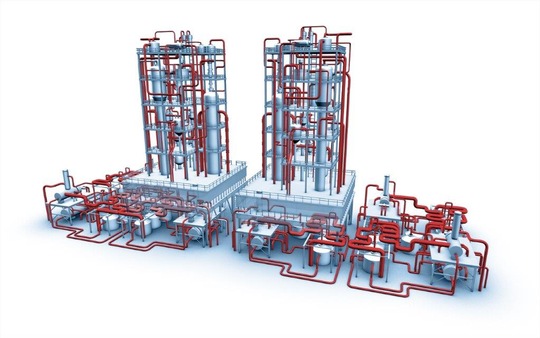

For more than 50 years, experts from the energy sector have come together at the OTC for an open exchange of opinions and ideas. This year, Schwarze-Robitec will also be there. The traditional German company with headquarters in Cologne is one of the world’s leading manufacturers of tube cold bending machines for various industries and applications. In the offshore industry, the robust CNC tube cold bending machines of the Heavy Duty series in particular play out their advantages: They bend tubes of different dimensions — from 0.16 to 16.5 inches (4 to 420 millimeters) — in complex geometries with high repeatability and precision. This enables the company to provide users with time- and cost-efficient production. Thanks to the high-quality processing, the precisely fitting pipes are particularly wear-resistant and dimensionally stable.

The experts know the complex requirements of the offshore industry inside out — and meet them with comprehensive advice, in-depth know-how and bending solutions tailored precisely to user needs. With a service and sales team operating from Grand Rapids, Michigan, the Group is represented on the North American continent.

At the trade show in Houston, the tube bending specialists will be on hand at booth 1258 to answer all questions relating to efficient and economical tube bending and look forward to exchanging ideas with interested trade visitors.