Glatt Ingenieurtechnik is exhibiting for the first time at IFAT, the world’s leading trade fair for environmental technologies in Munich. The focus of the presentation will be on the patented PHOS4green process for recovering phosphorus from sewage sludge ash and converting it directly into ready-to-use phosphate or compound fertilizers. At booth A4.509, the process expert will provide information on the innovative procedure, which is already being successfully applied on an industrial scale.

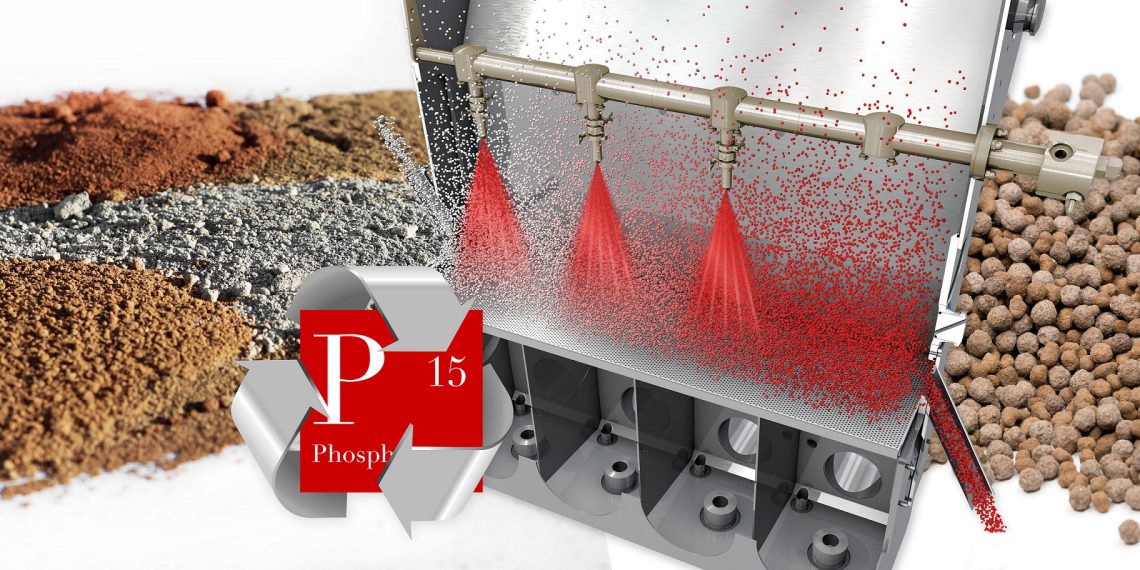

Specialists worldwide are currently conducting intensive research into concepts that can close the material cycle for the essential raw material phosphorus. One result of this research is the company’s two-stage process. It breaks down phosphorus from sewage sludge ash and then converts it into fertilizer granules that can be used directly. No residual materials remain. The process has been used in an industrial production plant in Haldensleben since May 2021. The fluid bed plant there for spray granulation runs in continuous operation; the fluid bed granulator installed is designed for a capacity of 60,000 metric tons of phosphate-containing straight and compound fertilizers per year.

Website provides comprehensive information

On its microsite on the subject, the Group provides comprehensive information on the technology and on possible applications such as phosphate-containing standard and specialty fertilizers. The website also provides information on current research projects as well as options for heavy metal removal from the ashes. Studies have confirmed the plant efficacy of various PHOS4green fertilizers compared to commercial fertilizers.

Technical papers published on the subject as well as references to events and platforms where experts can be contacted complete the digital offering. The presence at IFAT also provides the ideal setting for personal discussions.