Beumer Group, a single-source provider for filling, palletising and packaging technologies, develops complete packaging lines with perfectly compatible components. The right palletising technology is key to achieving optimally packaged load units and for the secure transportation of bags, buckets, packages or canisters. As a system supplier, the Group customises these systems, both the Beumer paletpac and the Beumer robotpac, to match the individual customer’s needs and takes product characteristics, packing patterns and pallet sizes into consideration. Both systems handle the items with care and stack them in an optimal pattern.

Secure and neat stacks of bulk material

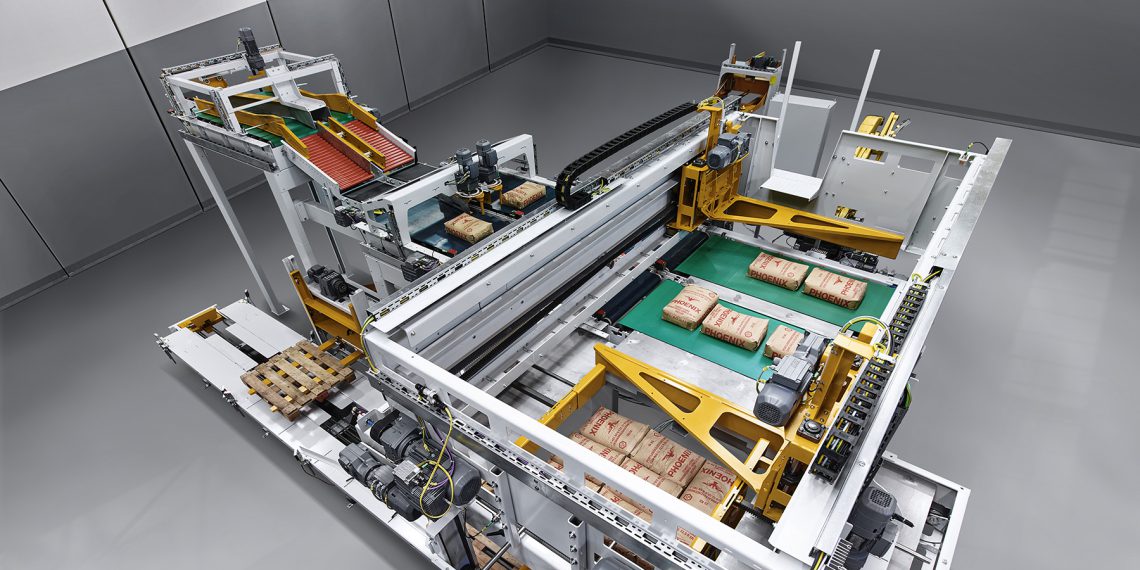

Products for the (petro)chemical industries are stored in special bags, barrels, canisters, cartons or buckets. The company offers different solutions, depending on the packaged items. The paletpac is suited best for bulk material. This construction series stacks the bags, that might have been filled by a fillpac FFS, in a stable and precise way on the pallets. The bags are made out of paper, polyethylene or polypropylene and are available in two different designs: flat valve and valve bottom bags.

The high-capacity machine palletises bags up to a pack height of 2,400 millimetres, in every technically possible packing patterns and on any commonly used pallet size — including intermediate sizes such as 1,400 x 1,200 millimetres. A multi-program interface enables the user to set parameters easily and quickly. The machines of this construction series can palletise up to 2,500 bags per hour, the high-capacity version up to 5,500 per hour.

A good position

The paletpac can be provided with a bar-type, clamp-type or twin-belt turning device to position the filled bags quickly, ensuring their dimensional stability. The latter offers a great advantage compared to conventional turning machines, because the system’s components move the bags without mechanically deforming them: “Two parallel driven belt conveyors move at different speeds and turn the bags quickly into the desired position,” explains Baumeister. The intelligent control of the twin-belt turning device also takes the dimension and weight of the filled bag into consideration. Exact positioning, specified by the preset packing pattern, is achieved. No adjustment is necessary even with a product change. Creating precise patterns during the layer and stack formation result in stable bag stacks. Multiple pallet loads created with the paletpac can even be stacked one on top of the other to save storage space.