In theory, the approach sounds quite simple: find a protein that cancer cells absolutely need to survive and develop an active ingredient that initiates the destruction of this protein — and the perfect cancer drug is ready.

A research team at the University of Würzburg has already proven that this approach works in principle. However, because putting it into practice is not quite as simple as it sounds, and because this would go beyond the scope of a typical research project in a university laboratory, those involved have now set about founding a company. As part of the GO-Bio initial funding program, the German Federal Ministry of Education and Research is supporting them on this path with around 500,000 euros.

Clinical failure after positive results in the laboratory

“We are focusing on the so-called Aurora‑A protein — a protein kinase and a promising target in targeted cancer therapy,” explains Elmar Wolf, professor of tumor systems biology at the Department of Biochemistry and Molecular Biology at Julius Maximilians University Würzburg (JMU). Earlier studies have shown that in many tumors Aurora virtually gives the starting signal for cancer and is thus one of the main culprits in the development of leukemias and many pediatric tumors such as neuroblastomas.

It is therefore no wonder that intensive efforts are being made worldwide to find a substance that can switch off Aurora and prevent the cancer cells from multiplying unchecked. So far, however, success has been limited:

“Almost all major pharmaceutical companies have developed so-called kinase inhibitors for Aurora‑A. Almost all clinical trials with these inhibitors have not been successful.”

- Elmar Wolf

Small molecules lead the cancer trigger to the shredder

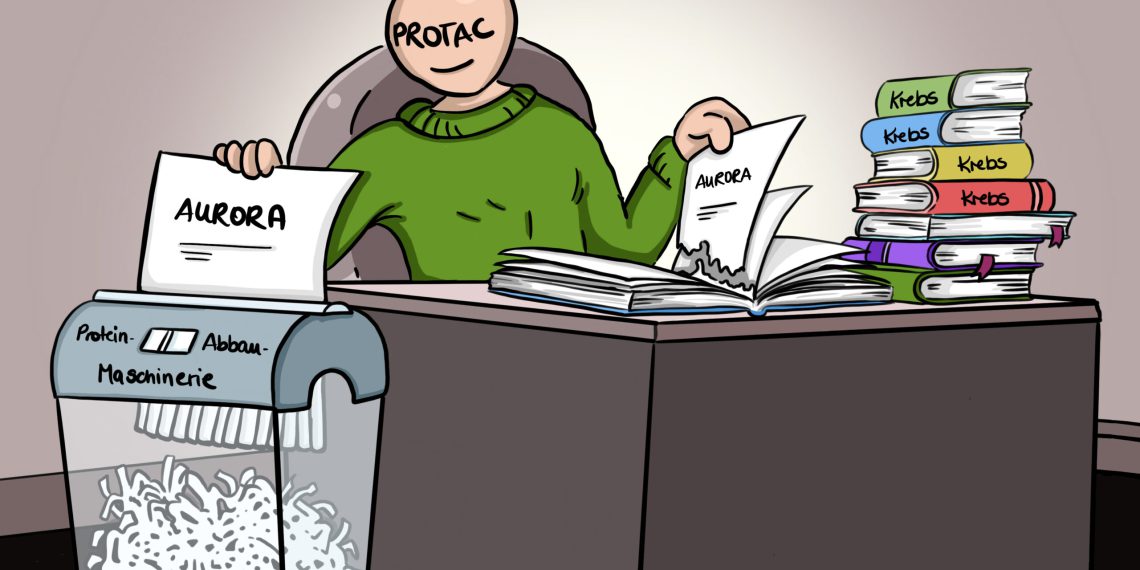

Elmar Wolf is convinced he knows the reason for this failure: “We and others have been able to show that Aurora‑A has important kinase-independent functions in cancer cells that cannot be inhibited by these inhibitors,” he says. So if you want to stop Aurora‑A, you not only have to block its kinase function, you have to make the protein disappear completely. The corresponding active ingredient is to be developed as part of the Go-Bio initial funding measure and the company to be founded.

The scientists are relying on PROTACs (proteolysis targeting chimeras). These are small molecules that bind to target proteins and feed them into the cellular degradation machinery — a kind of “shredder” inside the cell. For Aurora‑A, Wolf and his collaboration partner, Professor Stefan Knapp of Goethe University Frankfurt, developed the corresponding molecule a few years ago. JB170 — its scientific name — is one of the first molecules in the PROTAC class of substances to be produced in Germany. With numerous other PROTAC molecules in development, the teams from Würzburg and Frankfurt are among Europe’s leading academic working groups in this field.

Feasibility studies are at the beginning

“The results so far with JB170 as a new therapeutic strategy are very promising and interesting,” says Wolf. However, crucial experiments that clearly demonstrate feasibility still need to be done on the road to commercialization, he adds. Thanks to the Go-Bio initial funding, he says, this is now possible.

This feasibility phase will probably last two years; however, a market-ready product will not be on pharmacy shelves by then. “After the end of the feasibility phase in 2023, we plan to spend about three years on further studies of safety and efficacy and on optimizing the manufacturing process and formulation,” Wolf says. Clinical trials and the approval process could then begin in 2026. If successful, market entry is expected between 2030 and 2032.

If it is indeed possible to develop JB170 into a drug, Wolf expects it to have broad applicability. “We have so far been able to demonstrate the effect of JB170 with great success in leukemia and lung carcinoma cells. In addition, quite a few studies by other research groups suggest that tumors of the intestine, breast and liver are also strongly dependent on the function of the Aurora‑A protein,” says Wolf.

Support from the Research and Technology Transfer Service Center

The team also received great support on its way to spin-off from the Service Center for Research and Technology Transfer (SFT) at the University of Würzburg. “There, we had a highly competent contact in Dr. Iris Zwirner-Baier for all questions relating to securing patent rights to JB170 and paths to start-up,” says Elmar Wolf. Thanks to her intensive support, she made a significant contribution to the successful acquisition of the Go-Bio grant.