For the first time, researchers in the working groups led by Prof. Tobias Gulder of TU Dresden and Prof. Tanja Gulder of the University of Leipzig have succeeded in elucidating the biosynthetic mechanisms for the production of the natural substance cyanobacterin, which is produced in small quantities in nature by the blue-green alga Scytonema hofmanni. In the process, they also discovered a new class of enzymes for building carbon-carbon bonds. The (bio)chemists are thus significantly expanding the biocatalytic repertoire currently known from nature and opening up new, more sustainable biotechnological application potentials in medicine and agriculture. The results of the collaboration have now been published in the renowned journal Nature Chemical Biology.

The fact that nature is an excellent chemist is demonstrated by the abundance of molecules, the so-called natural substances, that it produces biosynthetically. These natural substances are also of central importance to us humans. They are used in many ways in our everyday lives, especially as active ingredients in medicine and agriculture. Prominent examples are antibiotics such as penicilins isolated from molds, the cancer drug taxol from the Pacific yew tree, and pyrethrins found in chrysanthemums, which are used to combat pest infestations.

Knowledge of nature’s construction kit is essential for the development and production of drugs based on natural substances. In this context, researchers from the working groups led by Prof. Tobias Gulder (TU Dresden) and Prof. Tanja Gulder (University of Leipzig) jointly investigated the biosynthesis of cyanobacterin, which is highly toxic to photosynthetic organisms and is produced in small quantities in nature by the blue-green alga Scytonema hofmanni. In their work, the chemists were not only able to elucidate the formation of the natural substance for the first time, but also discovered a novel enzymatic transformation for the formation of carbon-carbon bonds.

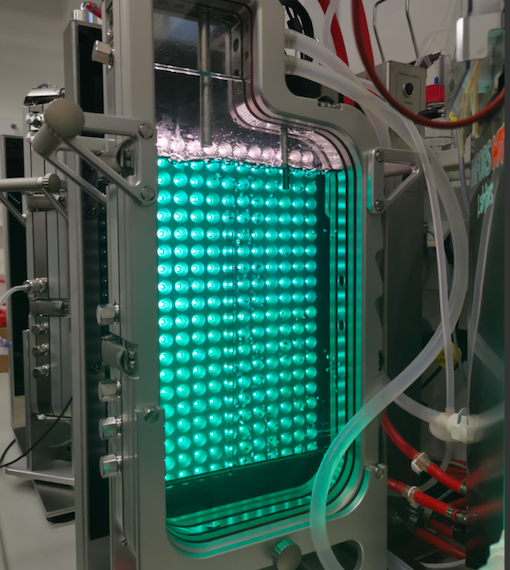

This work was made possible by combining modern tools from bioinformatics, synthetic biology, enzymology and (bio)chemical analytics. The focus was on how the central part of the cyanobacterin carbon skeleton is produced. The putative genes for this were first cloned by the method of “Direct Pathway Cloning” (DiPaC) and activated in the model organism E. coli as a cell factory. DiPaC is a new synthetic biology method previously developed in the laboratory of Tobias Gulder, professor of technical biochemistry at TU Dresden.

“DiPaC allows us to transfer entire natural product biosynthesis pathways into recombinant host systems very quickly and in a targeted manner,” Gulder explains. In the next step, the research team analyzed the essential individual steps of cyanobacterin biosynthesis by additionally producing all key enzymes in the host organism E.coli, isolating them and then investigating the function of each enzyme. In the process, they came across a previously unknown class of enzymes called furanolide synthases. These are capable of catalyzing the formation of unusual carbon-carbon bonds. In further studies of these furanolide synthases, these enzymes proved to be highly efficient in vitro biocatalysts, making them highly attractive for biotechnological applications.

“Furanolide synthases have provided us with a molecular tool that will allow us to develop more environmentally friendly methods for the production of active ingredients in the future and thus make our contribution to a more sustainable chemistry.”

- Prof. Tanja Gulder from the Institute of Organic Chemistry at the University of Leipzig

Next, the two research teams want to specifically search for these novel biocatalysts in other organisms as well, and thus find new bioactive members of this natural product class, as well as develop a biotechnological production and structural diversification of cyanobacterin. “Our work paves the way for the comprehensive development of an exciting class of natural products for applications in medicine and agriculture,” agree the two scientists.