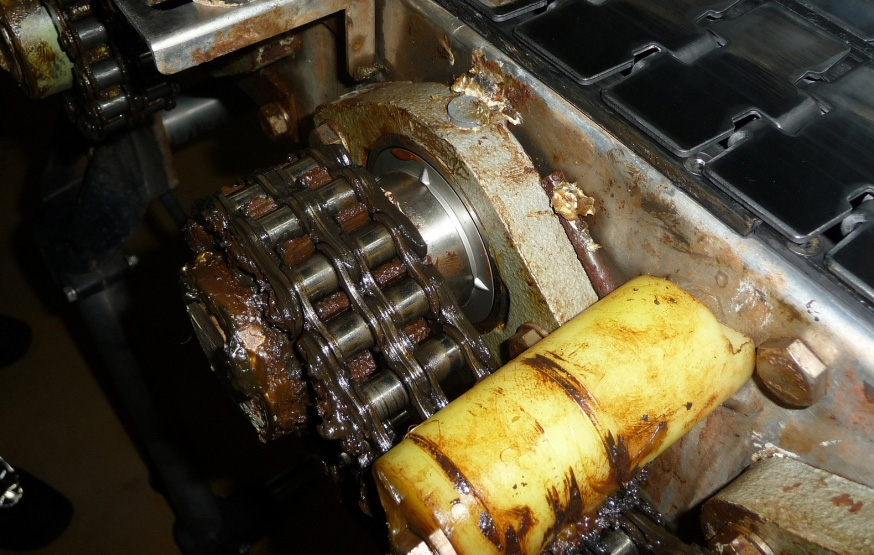

By changing to NSK Molded-Oil mounted-unit inserts, an international drinks producer has overcome repeated problems of premature insert failures on the drive system of four vital sorting conveyors. The move has improved service life notably, leading to an annual saving of more than €5000.-Image1.jpeg — One of the conveyor drives at the drinks plant, highlighting the harsh operating conditions for the mounted units

At the beverage plant, cleaning processes comprising a mix of water and chemicals were destroying the bearing seals and washing out the grease pack on the company´s existing mounted units. As a result, the inserts within the mounted units had to be replaced every 5 to 6 months, and re-greased every 3 weeks. The company was invited to find a solution to this problem in order to improve service life and reduce maintenance requirements.

After a thorough review of the application, NSK´s team of expert engineers concluded that a switch to Molded-Oil mounted-unit inserts would solve the issue.

The firm mounted units comprise two basic components: the insert and the housing. Each unit consists of a sealed single-row ball bearing with spherical external diameter and extended inner ring mounted in a pillow block or flanged housing. The spherical fit accommodates any initial misalignment.

Importantly, the lubricant within Molded-Oil inserts is durably incorporated inside a stable carrier medium, namely an oil-impregnated polyolefin resin. This type of lubricant cannot be washed away by liquids or steam, and prevents the ingress of contamination. Moreover, as the carrier only releases the lubricant slowly, sufficient lubrication is maintained over a long operating period. A further benefit is that the operating environment remains clean as no grease can leak out and no oil refilling is required.

Made from martensitic stainless steel, Molded-Oil inserts are ideally suited to applications which are in frequent and heavy contact with water.

One year on from installing Molded-Oil mounted-unit inserts, the drinks producer has reported no failures whatsoever, while the need for re-greasing has been eliminated. As a result, annual cost savings have been calculated at €5080.