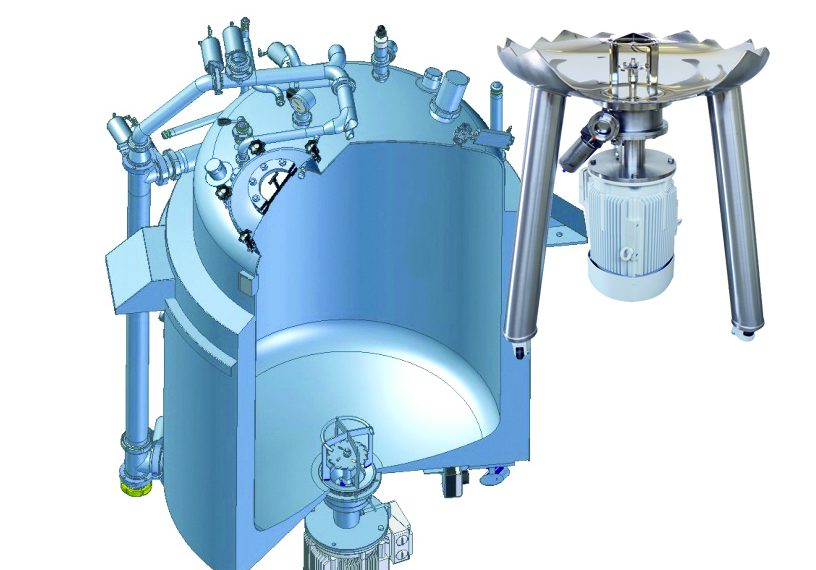

With the introduction of a newly developed bottom agitator, components and functions were combined to reduce maintenance and repair costs drastically.

This is achieved by the combination of several functions such as:

- Stirring and mixing

- Pumping via the recirculation line

- Cleaning in place (CIP)

- Discharge and transfer pump

The Cipmix is used for process operations like suspending, dispersing, melting and tempering. Through the recirculation pipe and tangential vessel connection the products are circulated with a high flow volume and can be tempered accurately and efficiently through the double jacket. The high pump rates also help with discharging and can replace transfer pumps even over long distances.Easy installation to an Ekato pre-phase vessel makes products for mass production in the cosmetics and pharmaceutical industries even more efficient. Simple products such as meltings for sticks, blocks or shampoos can be easily made on a pre-phase vessel. Furthermore, also fat phases can be melted with the Cipmix. The design and centric arrangement also enable working with very low fill levels and increase your flexibility.