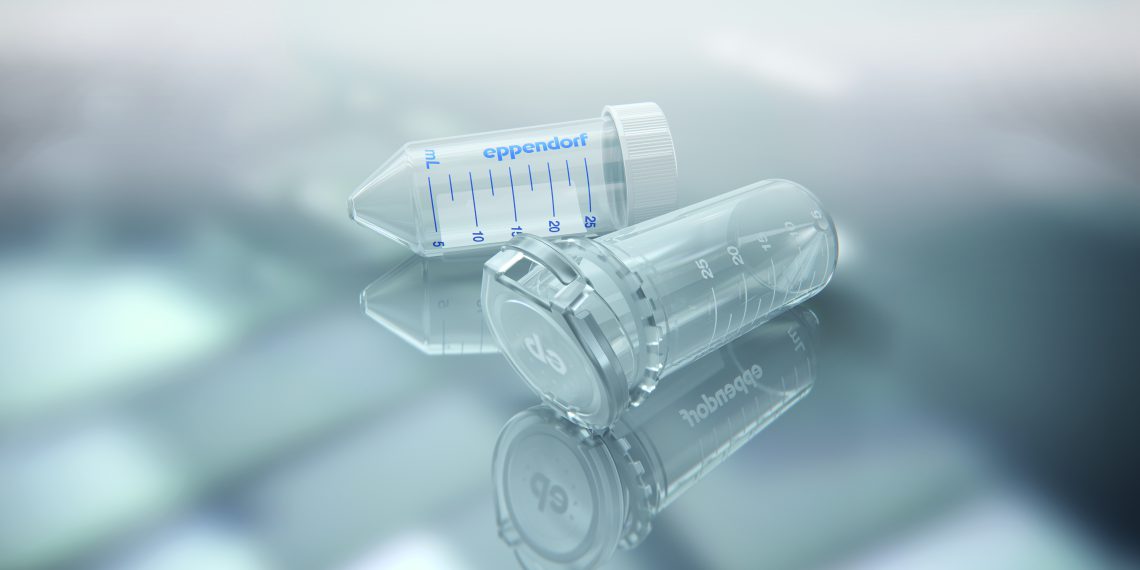

The new conical tube format of 25 mL, developed by the inventor of the “Eppi” tube, will advance the world of conical tubes. Working with sample volumes between 15 mL and 25 mL — often used in bacterial/microorganism culture as well as during purification of plasmid DNA/biomolecules, in cell culture or during assay preparation, leaves no option to researchers but to work with a traditional high-volume tube like the 50 mL conical tube. In recognition of this fact, Eppendorf has developed the Eppendorf Conical Cube 25 mL — available with either the new, patented SnapTec cap or with screw cap.

These conical tubes have the same diameter as conventional 50 mL conical tubes but a ~20 % lower height. This allows space-saving storage, for example in freezers. Additionally, the consumption of valuable raw material is reduced by 26 % for the screw cap 25 mL conical tube and by 20 % for the SnapTec cap 25 mL conical tube compared to a conventional 50 mL tube. Proportionally, laboratory waste of conical tubes will therefore also be reduced.

The wide opening, combined with the lower height, offers easy sample access. When working with low-volume pipettes and tips, the risk of cross-contamination between pipette and tube by touching the inner tube wall is reduced to a minimum. Premium raw materials, without the use of plasticizers and biocides during manufacturing, ensure highest sample integrity and optimal sample and pellet visibility.

The most innovative feature is the patented Snap Tec cap, which is unique within the conical tubes market. This cap is firmly connected to the tube. No need to put the cap on the bench, running the risk that caps from different tubes may become mixed up or contaminated. The Snap Tec cap allows single-handed opening and closing for quick liquid extraction or addition of sample. This is particularly advantageous in multistep lab protocols.

Of course, the Conical Tubes 25 mL are directly deployable. Straightforward integration into the existing laboratory environment is ensured. Concurrently, Eppendorf provides a full system of components. Adapters for both tube variants to be used in centrifugation rotors for 50 mL conical tubes are available, as well as adapters for Eppendorf Thermo Mixer C and Thermostat C, Tube Holder for Eppendorf Mix Mate, Storage Box, Tube Rack and Single Tube Stand.