At Powtech 2019, Coperion and Coperion K‑Tron will present their versatile bulk materials handling solutions for various process steps at their booth no. 4–290 in Hall 4. Along with the newly redesigned stainless steel WYK diverter valve for CIP cleaning and the ZV rotary valve, now also available in larger sizes, visitors will be impressed by the variety of components and products for safe and economical bulk materials handling that Coperion and Coperion K‑Tron offer.

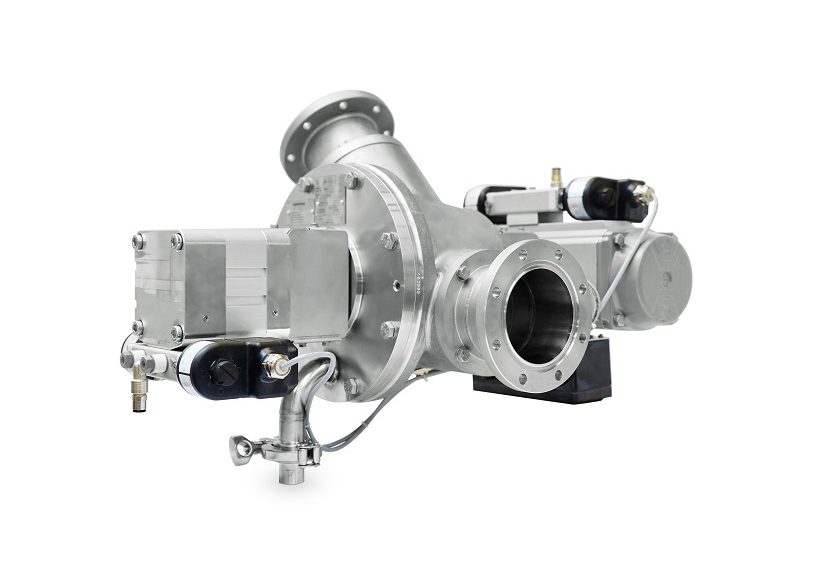

New WYK Bulk Material Diverter Valve

For parts used in manufacturing processes in many sectors of the food, pharmaceutical and chemical industries, the highest requirements in hygiene and purity apply. Moreover, frequent product changes and difficult product characteristics require regular wet cleaning. If cleaning expenditures can be minimized, companies can save significantly on time and costs.

Coperion addressed these issues more than ten years ago, developing the WYK for powder and pellets, which was awarded the Innovations Award by the Powtech exhibition in 2006. The diverter valve enables CIP applications to fulfill required criteria especially in the food sector that come down to one thing: The diverter valve must be absolutely clean and free of contamination after wet cleaning — with no additional disassembly or manual cleaning. This saves time, effort and costs since manual post cleaning is not necessary. In doing so, the WYK diverter valve can easily be installed even at points that are poorly accessible.

Throughout its inception, Coperion has continued to develop the WYK diverter valve based upon the collective experience of past years. Its innovative basic function has not changed: During bulk material conveying, the conical rotor seals the conveying pipes to each other. During CIP cleaning, the rotor is minimally pulled out of the housing and flushed by the cleaning fluid. Now, the diverter valve has been optimized according to current EHEDG guidelines (Class I EL certification is currently in process). Coperion redesigned and optimized the CIP-capable pipe sealing such that now operation with even the finest powders is possible. The pneumatic drives are separated — for turning and pulling the rotor, respectively — so that the rotor is supported on both sides. Along with its compact design, the diverter valve offers an improved cast design with increased surface quality. All materials conform to (EC) Regulation no.1935/2004 and the sealing materials are FDA-conform as well. Moreover, further flange connections, such as those per DIN 11864, can be realized simply on the housing.

The diverter valve is available in sizes DN 65, 80, 100 and 125. It is also available as a standard stainless steel diverter valve without the CIP cleaning function for non-wet cleaning applications. The diverter valve will be offered in Europe and Asia beginning of September 2019 and is expected to be offered in the USA by year end.

New ZV rotary valve housing for pellets and coarse-grained products

Coperion’s redesigned and optimized ZV rotary valve is now also available in sizes from 400 to 630. In comparison to its predecessor models, it excels above all with a lower granulate destruction during operation. Coperion enlarged the inlet cross section with additional pellet deflecting profiles. In doing so, an increase in throughput performance of up to 20% results.

Even noise emissions from leakage gas expansion, which constitute the primary source of noise in high-pressure rotary valves (up to 3.5 bar differential pressure), have been markedly reduced with a new expansion opening design. Additionally, Coperion integrated the transition of the elongated opening to a pipe connection within the cast. Beyond reducing the noise emission, an adapter is likewise no longer required. Moreover, the ZV rotary valve now has a standard-compliant pipe connection.

Coperion at the Powtech 2019: Hall 4, Stand 290