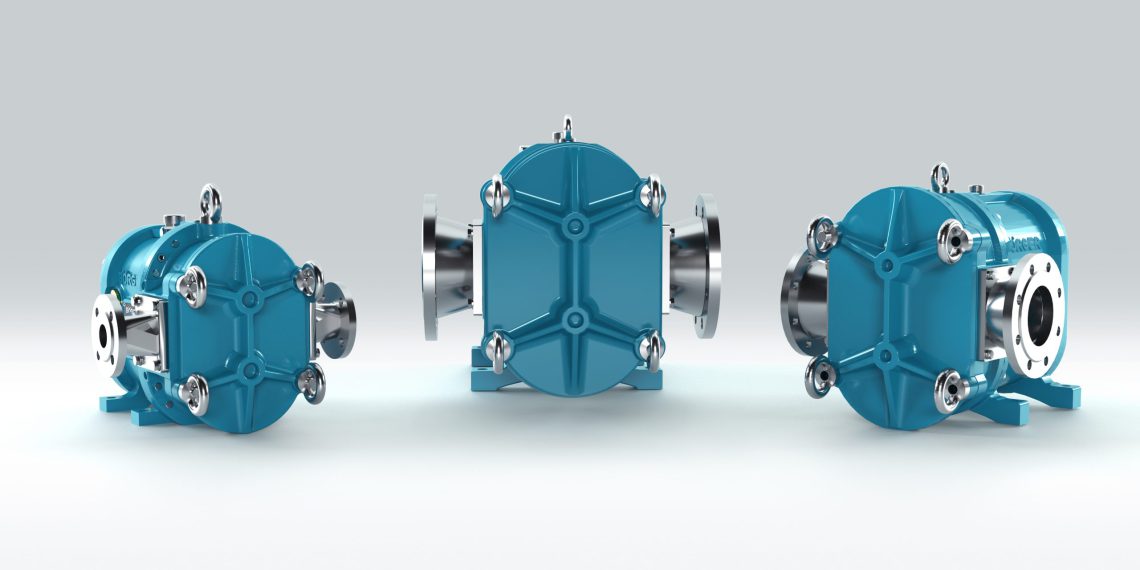

Börger surprises the pump world with the new generation of BLUEline rotary lobe pumps. The high-tech pump will initially be available in six sizes with flow rates of up to 110 m³/h. The manufacturer promises outstanding volumetric efficiencies and maximum flexibility in the sealing area.

The company is known for high-quality rotary lobe pumps with flow rates of up to 1,450 m³/h. Now the Münsterland-based engineering company is presenting the new generation of its rotary lobe pumps.

“Our knowledge from more than 30 years of pump construction has gone into the development of the BLUEline Nova pump. With the help of countless flow simulations and test bench runs, we were able to further improve the pumps.”

- Alois Börger, Managing Director

Rotary piston and housing its made for each other, says Alois Börger. The newly developed, one-piece Dius rotary piston enables almost pulsation-free pumping at pressures up to 12 bar. The wide sealing surfaces of the coiled rotary piston prevent backflow of the liquid. In order to be able to use the full effect of the two-lobe rotary lobe, Börger has revised the pump chamber. Here, optimizations were made primarily to the geometry of the inlets and outlets and the wrap angle of the housing. “We were able to significantly improve the volumetric efficiency of the pump. For this purpose, we perfectly adapted the delivery chamber to the rotary lobe geometry in terms of flow,” explains Alois Börger.

Börger offers the BLUEline Nova with and completely without protective housing lining. The clean version comes without a protective housing lining. The low dead space pump can be cleaned according to the CIP (Cleaning-In-Place) and SIP (Sterilization-In-Place) hygiene processes.

For pumping abrasive, solids-laden media, the tough version of the BLUEline Nova is equipped with a protective housing lining. Thanks to a new mounting system, the Nova pump in the tough variant also has a previously unattained volumetric efficiency. In the event of wear, the lining can be replaced quickly and easily thanks to the MIP® (Maintenance in Place) design.

The large seal chamber of the Nova rotary lobe pump offers space for various sealing systems. Connection of external supply systems is possible without any problems.

The pump can be driven by various motors. If desired, the drive can be mounted directly on the pump. The elimination of the coupling makes the unit even more compact. In addition, the base frame can be dispensed with in this variant.

Like all Börger pumps, these rotary lobe pumps can be manufactured in accordance with the European ATEX directives for intended use in potentially explosive atmospheres. An API 676-compliant design, manufacture in accordance with FDA regulations or design as a technically tight pump in accordance with German TA-Luft requirements round off the wide range of options.