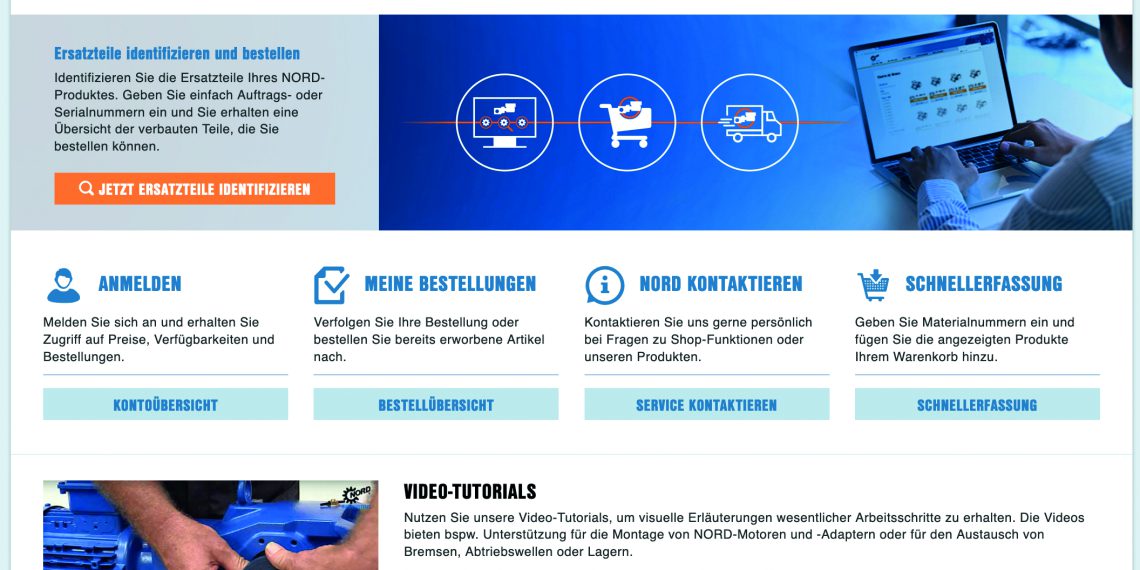

In NORD’s new web store, customers can choose from an extensive product range. On request, the components can also be delivered by express.

The new e‑shop optimally complements the existing myNORD customer portal. In the online store, motors, frequency inverters and many other products can be ordered around the clock. One click is all it takes for the customer to see whether the desired component is available. He also finds out the price and the expected delivery time. Orders placed before 12 noon are shipped the same day, and express delivery is also possible.

“We are pleased to be able to further expand our service offering with the online store. Our new e‑shop will make ordering even easier and more convenient for users.”

- Peter Gatringer, Managing Director

Together with seven other employees, he looks after all customers in Austria — from medium-sized businesses to international industrial groups. In the medium term, the web store is to grow together with the customer portal to form a central online platform that offers comprehensive options for configuring and ordering NORD products. NORD web stores already exist in Switzerland, the USA, France, Great Britain, and Germany.