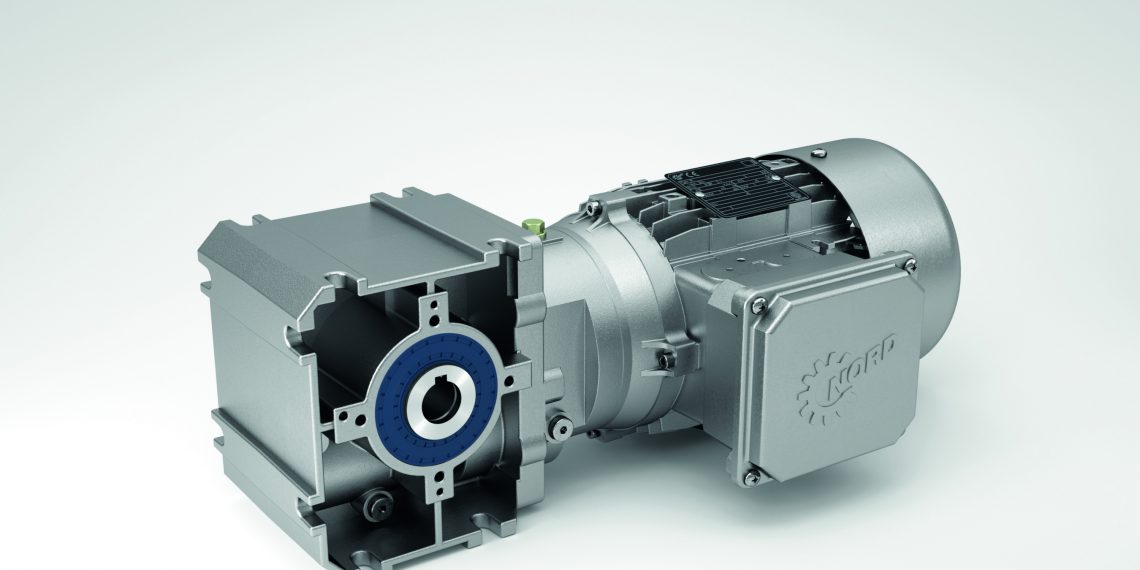

Nord Drivesystems has thoroughly redesigned its two-stage SK 02040.1 helical worm gear unit. The new SK 02040.1, made from strength aluminium, replaces the previous cast iron product. The one-piece die cast Uunicase housing guarantees maximum strength and rigidity with low weight. In addition, aluminium is considerably more corrosion-resistant than steel and can be further protected with the aid of additional measures such as the highly effective nsd tupH surface treatment.

The SK 02040.1 has a wide power range from 0.12 to 1.1 kW and an output torque of up to 100 Nm. The wide range of speed ratios (from 5.37:1 up to 330:1) enables optimum adaptation to the customer’s requirements. The new gear unit is available in a universal foot flange version and offers ultimate versatility through many equipment versions and includes mounting options such as flanges and torque arms. All versions are available with solid or hollow shafts. The motor can be mounted directly without a coupling of adapter (IEC or NEMA).

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more