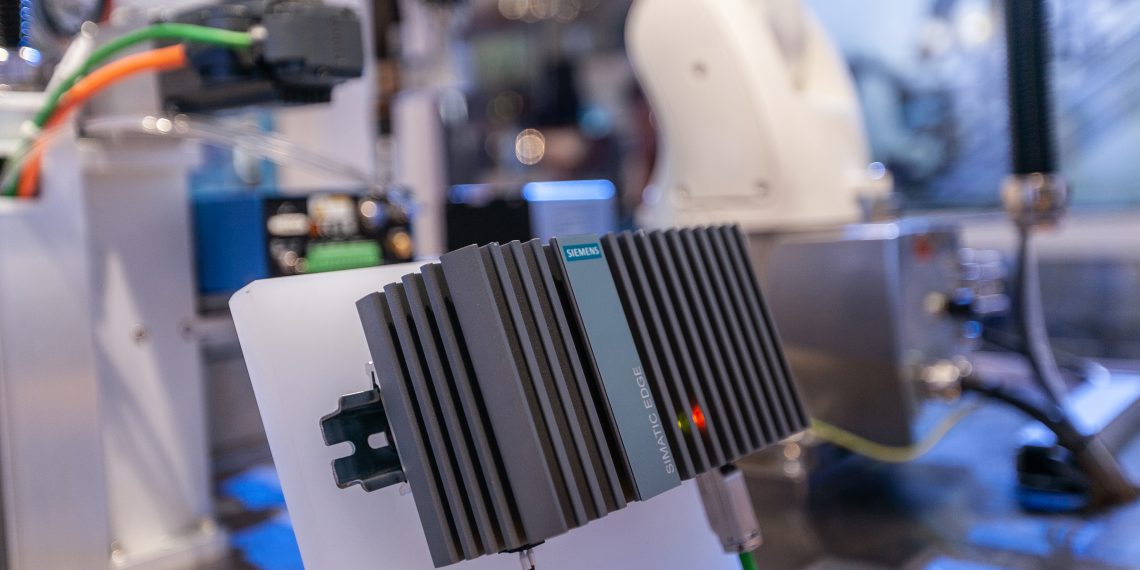

At the SPS IPC Drives 2018, Siemens showed a newly developed hardware platform for edge applications as part of its Siemens Industrial Edge concept: The compact Simatic Edge Device works on the basis of the embedded industrial PC Simatic IPC227E, and features integrated connectivity to automation on the machine level. This allows manufacturing data to be captured and processed directly at the point of production. If there is a change to the framework conditions underlying the industrial application, Industrial Edge offers facility to adjust software applications on the Edge Device, keeping them right up to date using functional, feedback-free updates. The hardware comes with a closed all-metal housing, ensuring maximum industrial functionality for flexible, maintenance-free use under even the harshest of conditions. Rapid commissioning is guaranteed using pre-installed Edge software.

Industrial Edge

Siemens Industrial Edge affords users the opportunity to close the gap between classic local data processing and cloud-based data processing to suit individual requirements. Edge computing enables the local feedback-free processing of large data volumes practically in real time. Industrial Edge also enables users to cut the costs of data storage and transmission, as large volumes of data are processed in advance and exclusively relevant data is subsequently sent to the cloud or the company’s own internal IT infrastructure. Siemens Industrial Edge supports cloud transmission protocols for MindSphere, the open cloud-based IoT operating system from Siemens. In future, it will also support Message Queuing Telemetry Transport (MQTT), which will additionally guarantee the flexible exchange of data with other systems and clouds.

Savings through edge computing in the Siemens Electronics Factory Amberg

In the factory in Amberg, a printed circuit board cutting machine is used for the manufacture of Simatic products. During a milling operation, fine milling dust is produced which exerts an aggressive impact on the machine. This can cause the spindle bearing to jam, and potentially result in unscheduled machine downtime. To prevent this from happening, a number of the machine’s operating parameters are analyzed using artificial intelligence with a view to detecting any anomalies in spindle behavior which would indicate the possibility of an impending failure. This is done by transmitting data picked up by the sensors to the Edge device for analysis. A machine learning algorithm calculates the anomaly value in real time. A rise above a predetermined threshold value indicates that a machine failure is imminent. This Edge application enables cases of bearing erosion and machine downtime to be predicted between 12 and 36 hours in advance of an actual failure. In the event of anomalies, the machine spindle can be exchanged as part of the next scheduled service before a failure can cause costly unplanned downtime.