Coperion Pelletizing Technology, introduces improved dual bearing strand pelletizers which have been re-engineered based on field experience and current market demands. The SP140, SP240 and SP340 models in the SP series have been equipped with a variety of enhanced features for easy, rapid handling and optimized pellet quality. Moreover, the company has developed a new proprietary technology for cutting gap adjustment which impresses users with increased comfort and speed compared to tried and true classic systems. The new generation of the strand pelletizers will be on display for the first time at K 2019 in hall 14 at booth 14B19.

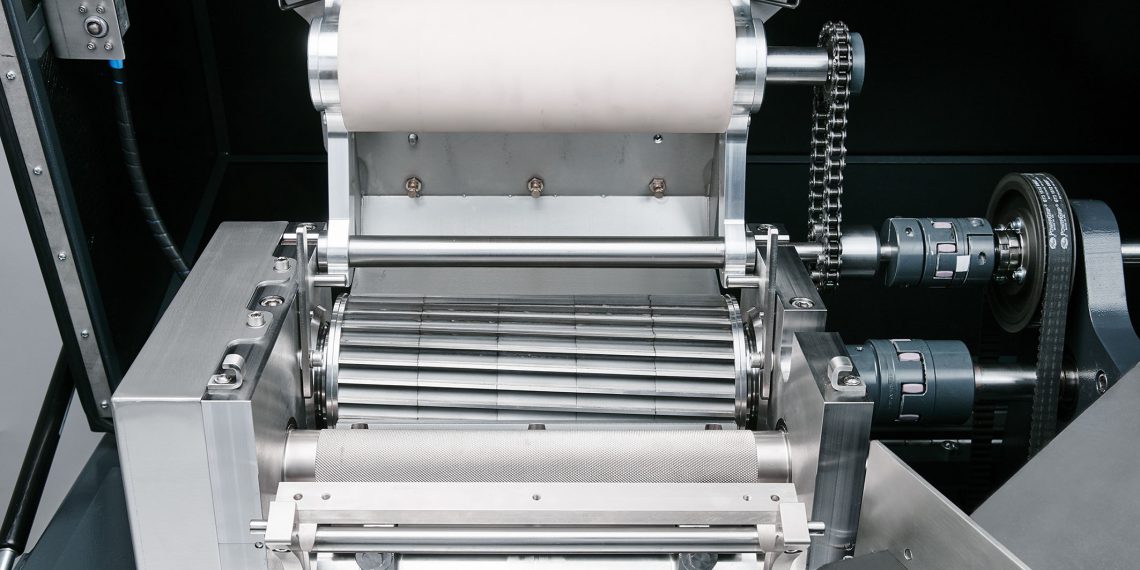

This new cutting gap adjustment (patent pending) constitutes the heart of the re-engineered strand pelletizers. Conventional solutions like eccentric screws or compression-tensioning screws present disadvantages such as non-linear movements, potential dirt pockets on the product, several setting steps or subsequent shifting from additional locking mechanisms. The unique new technical solution from Coperion Pelletizing Technology offers faster and more comfortable adjustment. Fine adjustment is also simpler and more precise, as it can be done by hand without tools. Likewise, the integrated spring pre-tensioning eliminates the screws’ free clearance, markedly reducing machine setup times.

Optimization reduces service and downtime

Along with the more compact design and integration of the operation panel into the machine, the reworking of the interior space counts first and foremost among further new developments. The robust cutting tools have been installed closer to one another, thus enabling a shorter, unguided strand length in the pelletizer and the best possible cutting results, especially with soft materials. This new construction results in less dead space in the interior which, together with optimized edges and fewer free surfaces, provides improved cleanability. Furthermore, the new quick change cutting chamber system really impresses users. The complete cutting area is accessible without tools and the cutting unit can be exchanged quickly and easily. This quick change minimizes machine servicing times and downtimes. Likewise, Coperion Pelletizing Technology reworked the intake area; whereas this previously used a conical construction, today a straight intake allows strands to be optimally side fed into the pelletizer. Strands are therefore fed directly into the pelletizer without deflection. Side panels on the intake roller prevent individual strands from breaking free. Moreover, intake proceeds without splits or gaps so that strand tears and bevel are avoided during intake. Additionally, Coperion was able to increase the operating width by 20 mm so that higher throughputs are now possible. Pelletizing in this new design also features improved soundproofing. Along with the more compact interior cutting space and the resulting smaller sound chamber, all motors are now housed under the base plate and are noise insulated there. In so doing, machine operation at a very low noise level is possible.

Pelletizing with a multitude of options, suitable for every need

These new, optimized strand pelletizers are available now, impressing manufacturers not only with these new developments but with proven technology as well. Among these, for example, are a pellet outlet chute with soundproof cladding, a frequency-controlled drive, and pneumatic control for feed roll pressure. The baseplate is mounted on vibration-insulating rubber pads; likewise, the pelletizer is installed on lockable rollers for more flexibility. In the control cabinet, transfer signals are built in for remote control; moreover, the pelletizer is equipped with a safety device (Haake system), in place of the classic retarding spindle. Operation is thus even more ergonomical and safe.

Further features are available as options for Coperion pelletizers, including a high temperature-resistant upper feed roll for long service life as well as wear-protected or corrosion-protected cutting rotors for highly filled or reinforced materials. Increased drive power for high processing demands is likewise available as a dual drive — with a driven upper feed roll for improved intake. Optional cooling for the feed roll and the cutting head to cool the entire cutting chamber ensures a longer service life. Coperion Pelletizing Technology also offers control cabinet climate control for especially demanding environmental conditions.

Coperion at the K 2019: Hall 14, Stand B19