Yokogawa Electric Corporation plans to launch its newly developed TDLS8200 tunable diode laser spectrometer as part of its OpreX™ Analyzers product family on May 6, 2021. The new product features the same low installation cost, high measurement stability and high reliability as its predecessor, the TDLS8100, and can simultaneously measure oxygen, carbon monoxide and methane gas concentrations directly and at high speed.

Development background

Excess air supplied during combustion control in heating furnaces absorbs heat in the furnace before exiting through the exhaust stack. This not only leads to heat loss, but can also generate large amounts of nitrogen oxides and sulfur oxides, which are a major cause of air pollution. On the other hand, if there is insufficient air supply, complete combustion does not occur, resulting in energy losses, emission of carbon monoxide and black smoke, and residual methane. Carbon monoxide and methane are flammable gases that can easily form an explosive mixture with air if they accumulate in a furnace. Therefore, in oil and gas, electric power, iron and steel, petrochemical, and ceramic plants, the concentrations of oxygen, carbon monoxide, and methane in furnaces must be monitored to ensure an efficient, environmentally friendly, and safe combustion process.

Features

1. Efficient combustion and high safety through stable, simultaneous measurement of oxygen, carbon monoxide and methane.

The main feature is the dual laser light source and optics, which enables simultaneous measurement of oxygen, carbon monoxide and methane concentrations for efficient combustion control. The direct measurement system is based on the use of lasers, which are easier to maintain than conventional sampling systems and more robust than catalyst-based sensors. This provides stable, simultaneous and lossless measurement of oxygen and carbon monoxide concentrations.

2. Easy replacement of sampling systems

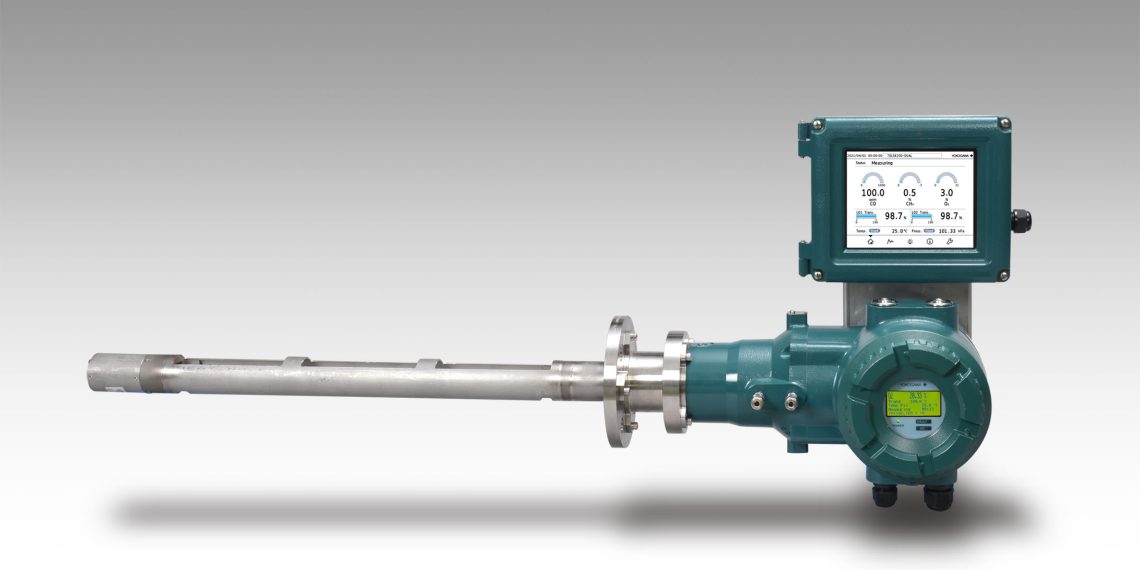

The new product is an easy-to-install diode laser spectrometer with in-situ probe. Existing sampling systems can be quickly and easily replaced, which can be installed at the same port as the previous instrument. Since sample collection or preparation systems are unnecessary, little floor space is required.

3. Planned second version for measurements in environments with temperatures up to 850°C.

Available May 6, 2021, the spectrometer is designed for high temperatures of 600°C, making it ideal for use in boilers and exhaust ducts. A second version of the TDLS8200 for measurements at temperatures up to 850℃, such as when used in heating furnaces, is scheduled for release later this year.

Laser-based gas analyzers from Yokogawa

Yokogawa’s laser-based gas analyzers operate on the principle of tunable diode laser spectroscopy (TDLS) for concentration determination in gases. They offer best-in-class real-time performance because they are installed on channels and do not require a sampling system, so they can measure concentrations directly and at high speed. They use a spectral domain method that calculates gas concentration from the area in a light absorption distribution pattern — enabling accurate and stable concentration measurement even in an environment with temperature and/or pressure variations or in the presence of other types of gases or large amounts of dust.

Since their launch in 2008, Yokogawa’s laser gas analyzers have gained worldwide acceptance for their high reliability and performance in even the most challenging environments. Previously, Yokogawa had two models in its lineup: the TDLS8000 and the TDLS8100. The former is equipped with a separate laser light source and detector and is suitable for concentration measurement in high-temperature and high-pressure gases, even with high dust levels. The TDLS8100 is capable of measuring the concentration of gases whose flow rate ranges from 1 to 30 meters per second. With the addition of a third model to this series, simultaneous measurement of multiple gas types is now possible.