Multi-product reactors with enhanced heat transfer requirements are often equipped with simple radially working mixing systems as anchor-/frame‑, blade- or maxblend-impellers.

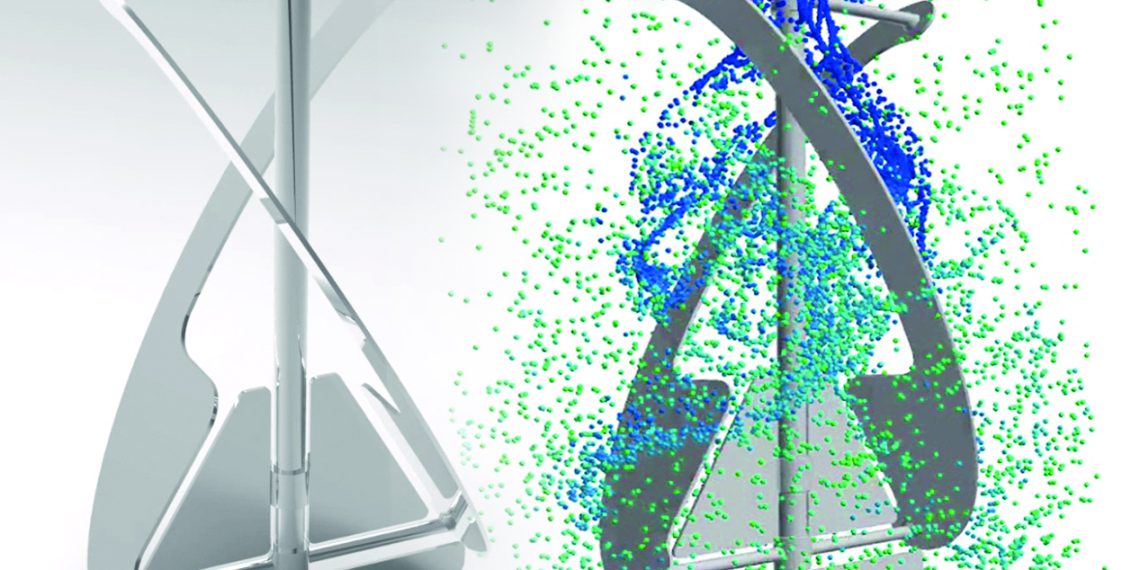

To improve the performance of such reactors Ekato has developed the Varioblade, which is a flexible, modular impeller with an optimized split between axial and radial flow components by different shapes of the upper and lower impeller parts. Compared to standard frame- or blade type impellers, the blend times – especially in the mid-viscous range – can be improved by up to 50 %.

The Variobladeis not a close-wall-clearance system but operates in the center of reactors — typically with coils — where radial flow components are required. The positioning of the three elements – outer blade, inner blade and bottom anchor — can be varied. Therefore this impeller can handle different mixing task combinations with varying viscosities up to 50,000 cP.

As an example the modular inner blade can be adjusted to achieve a high dispersion effect. This is a significant advantage for multi-phase applications such as gas-liquid or liquid-liquid reactions.

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more