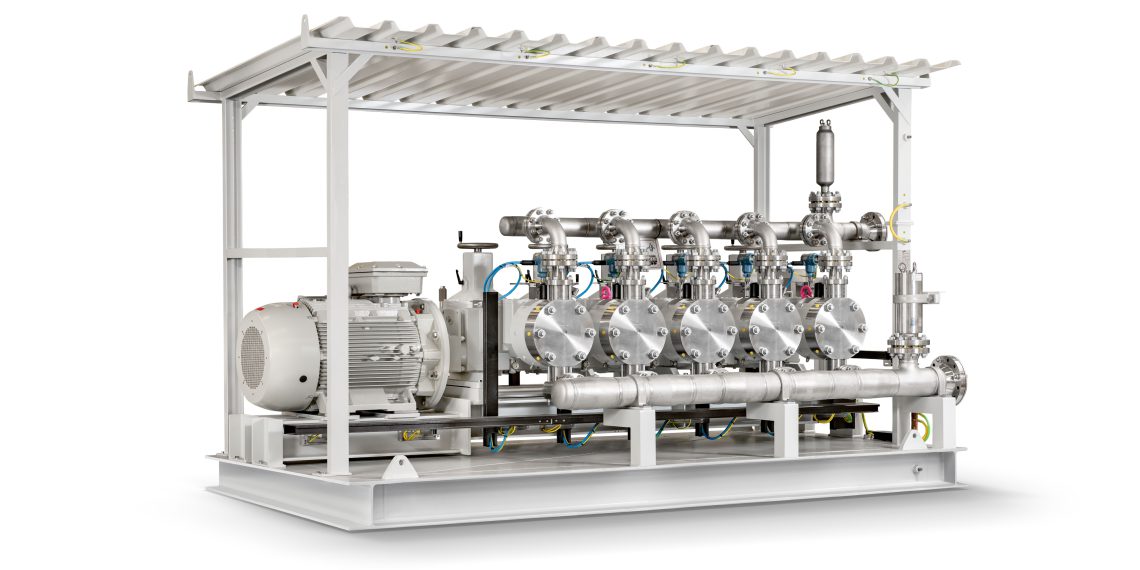

Lewa , based in Leonberg, Germany, has been working with its subsidiary Lewa Nikkiso Middle East for several years now to increase its market share in oil and gas extraction in the Middle East region. Through multiple successful projects in past years the firm has improved its market position substantially and made itself an ideal candidate for additional orders. The pump experts are currently manufacturing 40 pump skids for a gas field located 160 km southwest of Abu Dhabi. The goal is to use these skids to increase the production capacity of the field. The company won this project over many renowned competitors. Delivery has been announced for July 2019.

When a globally active oil and gas corporation wanted a solution for disposing the byproducts and waste created during production, it commissioned Lewa to supply 20 LDG5, 10 LDHB and 10 LDF3 ecoflow process diaphragm pumps. “With the help of our 40 pump skids, the fluids that occur are directed straight to the flare for combustion. Other waste materials are stored temporarily in tanks and disposed of as soon as the tanks are full,” explains Klaus Figgle, Project Manager of Engineering Oil & Gas at Lewa. At a maximum pressure of 43 bar, the three pump types achieve a flow rate of 5,000 l/h (LDF3), 18,000 l/h (LDG5) and 22,000 l/h (LDHB). Since the pumping medium has a high proportion of hydrogen sulfide, which makes it very corrosive and caustic, the pumps had to be built with Super Duplex stainless steel. The design also had to be able to handle the high vapor pressure of the gas and the high ambient temperatures. In addition to the extraordinary operating conditions, special technical solutions were also required. “For example, to account for the low pressure at the suction head, an angle valve was installed on the intake side of the pumps. We were able to satisfy all of the customer’s requirements in accordance with technical specifications and really demonstrate the advantages we provide over the competition,” reports Figgle.