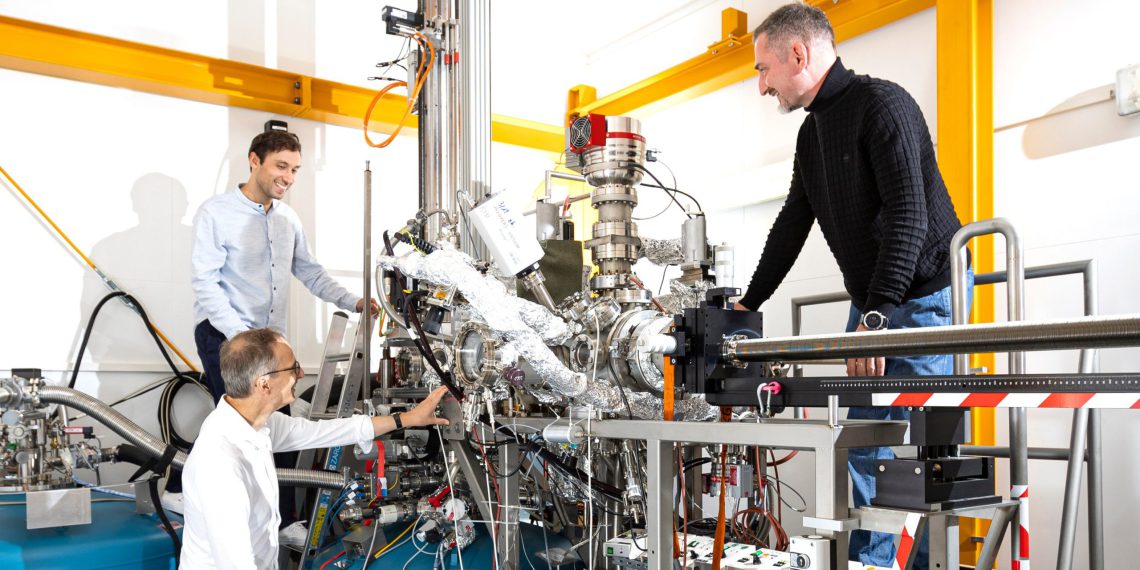

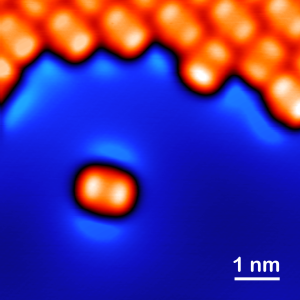

Scanning tunneling microscopes image materials with atomic precision and are versatile. Researchers have therefore been using them for many years to explore the world of the nanocosmos. Physicists at Forschungszentrum Jülich have now optimized such a device for the study of quantum effects. Thanks to magnetic cooling, their scanning tunneling microscope has no moving parts and operates at extremely low temperatures of up to 30 millikelvin with virtually no vibration. In the future, the instrument can help researchers unlock the unusual properties of quantum materials that are critical to the development of quantum computers and sensors.

The region near absolute zero is particularly exciting for physics. Thermal fluctuations are minimized at the low temperatures. The laws of quantum physics come into play, revealing special properties of materials. Electric current then flows losslessly without any resistance. Another example is so-called superfluidity: Individual atoms fuse into a collective state and move past each other without friction.

Such extremely low temperatures are also the necessary prerequisite for exploring and harnessing quantum effects for quantum computing. Researchers worldwide, including those at Forschungszentrum Jülich, are currently pursuing this goal at full speed. Quantum computers could be vastly superior to conventional supercomputers for certain tasks. But development is still in its infancy. A key challenge is finding materials and processes that make complex architectures with stable quantum bits possible.

“I believe a versatile microscope like ours is the tool of choice for this fascinating task because it allows imaging and manipulating matter at the level of individual atoms and molecules in a variety of ways.”

- Ruslan Temirov of Forschungszentrum Jülich

Over years of work, he and his team have equipped a scanning tunneling microscope with magnetic cooling for this purpose. “Our new microscope differs from all the others in much the same way that an electric car differs from a combustion engine,” explains the Jülich physicist. Until now, people relied on a kind of liquid fuel, a mixture of two helium isotopes, to bring microscopes to such low temperatures. “During operation, this cooling mixture continuously circulates through thin tubes, which leads to increased background noise,” Temirov says.

The Jülich microscope’s cooling device, on the other hand, is based on the adiabatic demagnetization process. The principle is not new. It was already used in the 1930s to realize temperatures below 1 Kelvin in the laboratory for the first time. “To cool the device, we only change the strength of the electric current flowing through an electromagnetic coil. Our microscope therefore has no moving parts, and operates virtually vibration-free,” reports Ruslan Temirov.

The Jülich microscope’s cooling device, on the other hand, is based on the adiabatic demagnetization process. The principle is not new. It was already used in the 1930s to realize temperatures below 1 Kelvin in the laboratory for the first time. “To cool the device, we only change the strength of the electric current flowing through an electromagnetic coil. Our microscope therefore has no moving parts, and operates virtually vibration-free,” reports Ruslan Temirov.

The Jülich team is the first to design a scanning tunneling microscope using this technology. “The new cooling technology has several advantages in practice. Not only does the imaging quality benefit, but the operation of the instrument and the entire setup are simplified,” says institute director Stefan Tautz. With its modular design, the Jülich quantum microscope is also open to technical advances, he adds, because upgrades can be easily implemented. “Adiabatic cooling is a real quantum leap for scanning tunneling microscopy. The advantages are so significant that we are now developing a commercial prototype as the next step,” explains Stefan Tautz. Quantum technologies are currently the focus of research. The interest of numerous research groups in such an instrument is therefore likely to be assured.