Researchers at the University of Oldenburg are analyzing data from the Lower Saxony State Office for Water Management, Coastal Protection and Nature Conservation. They found that higher temperatures could be the cause of smaller cells.

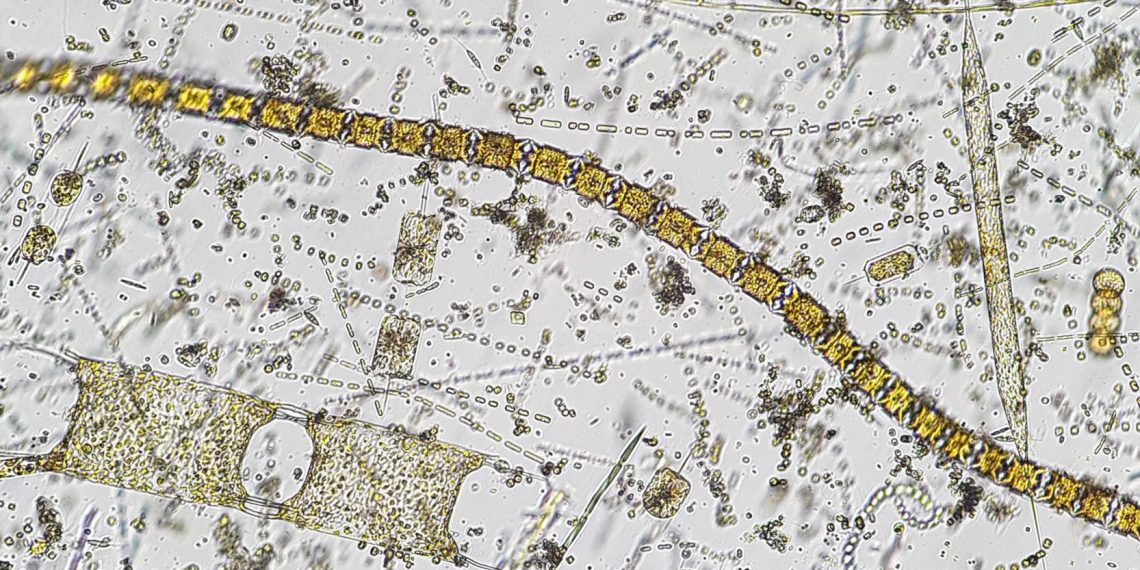

The cell volume of microalgae in the Lower Saxony Wadden Sea has decreased by 30 percent between 2006 and 2019. Diatoms in particular, known as diatoms, were affected by this shrinkage. This was reported by a team led by biodiversity expert Prof. Dr. Helmut Hillebrand from the Institute of Chemistry and Biology of the Sea at the University of Oldenburg in the journal Limnology and Oceanography. According to the team, the long-term trend could be due to rising temperatures and a decreasing level of the nutrient phosphorus in the North Sea. The decreasing cell size of unicellular algae could be an indicator of changes in the biotic community as a whole, the researchers said.

Phytoplankton — the extremely diverse group of unicellular algae that populate the light-filled uppermost layers of oceans, lakes and rivers — fixes about as much carbon dioxide per year as land plants and therefore releases half of all oxygen produced by photosynthesis on Earth. It therefore plays a fundamental role in the ecosystems of all bodies of water.

“The diversity of these organisms is remarkable, reflected for example in the extreme difference in size between the smallest and largest algal cells.”

- Prof. Dr. Helmut Hillebrand, director of the Helmholtz Institute

On the one hand, the size of the plankton cells is characteristic for each species. On the other hand, cell volume is also related to environmental conditions. “So far, however, we have only a few data sets on how the cell sizes of individual species, but also of entire communities, change over longer periods of time,” says co-author Dr. Lena Rönn from the Lower Saxony State Agency for Water Management, Coastal and Nature Conservation (NLWKN).

To find out whether the size of the protozoa changes at all, how different species develop and whether there is a connection with changing environmental conditions, Hillebrand and his colleagues evaluated data from more than 1,700 samples. The NLWKN had collected and counted these samples at 20 different sites in the Lower Saxony Wadden Sea between 2006 and 2019. The team did not simply look at the average size of all cells within a sample — as most previous studies have done — but analyzed the development of each species individually. This allowed Hillebrand’s team to investigate whether a temporal trend can be attributed more to a displacement of certain species or to an adaptation of the individual species to changing environmental conditions.

The analysis showed that over the observed period of 14 years, the average cell size decreased by about one third. Both the individuals of the individual species and the cell volume within the community as a whole shrank. “We were able to detect the reduction in cell size in 63 of 73 species studied, and unicellular algae with a shell of silica, known as diatoms, were particularly affected,” says Rönn. The researchers also observed seasonal fluctuations: In summer, the average volume of the cells was significantly smaller than in winter.

According to the analyses of the researchers around Hillebrand, the reduction in size can probably be explained by increased temperatures and lower nutrient availability. As the team writes, many organisms form smaller individuals at higher temperatures than under cool conditions. “If you compare tropical, temperate and polar habitats, you can find many examples of this,” Hillebrand says. This correlation was also known for phytoplankton. In tropical seas, the trend is exacerbated by lower nutrient levels.

The researchers expect that the reduction in algae will also affect other organisms in the Wadden Sea habitat, especially those that feed on them, including animal plankton and mussels. The study also demonstrates the importance of maintaining and sustaining time series for ecological research, Hillebrand said. It was only because the team re-determined the cell size of the algal species in each sample that the researchers were able to determine their shrinkage in the first place. The result also makes it possible to calculate more precisely the carbon contained in the plankton, an important input variable for models in environmental and climate impact research.