In China, Asahi Kasei’s wholly owned subsidiary Polypore International, LP (Polypore) and Shanghai Energy New Materials Techno-logy Co., Ltd. (SEMCORP), entered into a joint venture China to produce dry process separators. Production is scheduled to start in 2022 with a capacity of 100 million square meters per year and gradually increase to one billion square meters per year by about 2028.

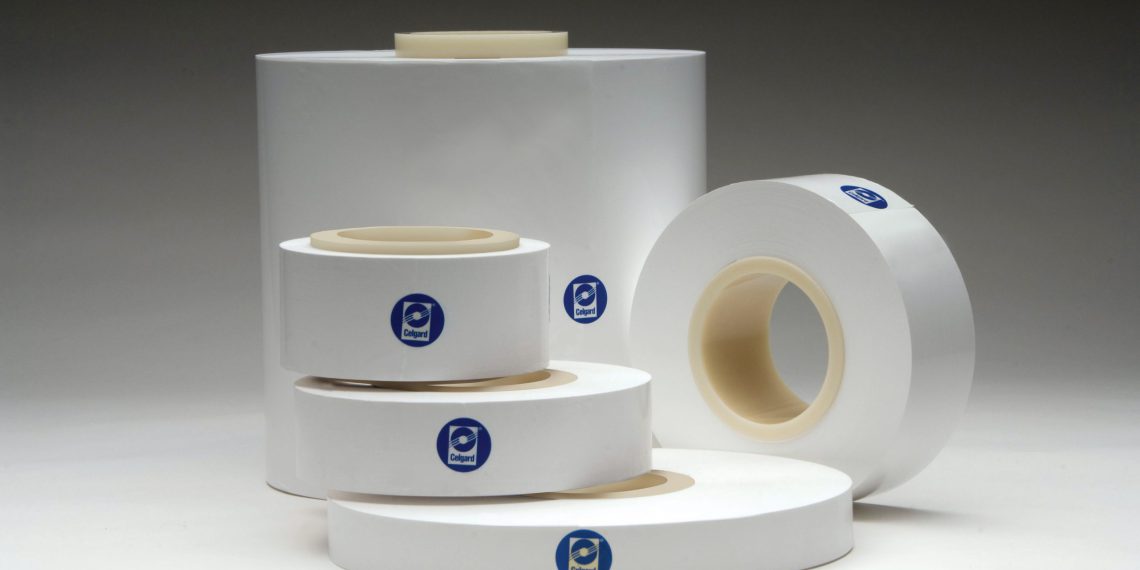

Based on a technology and intellectual property license valid for polypropylene (PP) dry process separators from Polypore subsidiary Celgard, LLC, the joint venture plans to manufacture and sell high-quality separator films for lithium-ion batteries (LIBs) in China. The separators will be used in energy storage systems and electric vehicles. The agreement to establish the joint venture was reached in January 2021.

The LIB market in China is the world’s largest and growing rapidly, with a focus on electric vehicle applications. The Chinese government is also continuously taking measures to decarbonize industry and society, so experts expect significant further growth in energy storage systems in combination with renewable energy. The newly established joint venture is intended to meet the growing demand for dry process separators for corresponding storage systems.

The joint venture will leverage Celgard’s dry process separator production technology, quality control expertise and intellectual property rights combined with SEM-CORP’s world-class manufacturing process and cost capabilities in China to expand into the Chinese LIB market for energy storage applications.

Celgard has been a market leader in research, development and manufacturing for over 40 years since the invention of the dry process LIB separator. With manufacturing expertise in thin dry process separators that enable higher energy density in high performance LIBs, Celgard has consistently provided its customers with technologically superior separators. The company also holds a broad range of patents for coated and uncoated LIB separators, in addition to energy storage systems used in electromobility and consumer electronics.

SEMCORP is China’s leading manufacturer of LIB wet separators and has more than ten years of experience in manufacturing and selling wet process separators. With six production sites in China and a total production capacity of 3.5 billion square meters per year, the Group offers more than 100 different types of separators, including base films and coated membranes. The company has had well-known LIB manufacturers as customers for many years and continues to excel in consistent quality, profitability, high productivity, and cost control.

The joint venture will offer technologies to meet the growing demand for LIB separators. It will acquire Celgard’s dry process membrane technology, manufacturing know-how and equipment under the technology license for single-layer PP and coextruded multilayer PP membranes. Production is scheduled to start in 2022 with a capacity of 100 million square meters per year and gradually increase to one billion square meters per year by about 2028.

“Combining Celgard’s expertise in technology, processing and material science with SEMCORP’s exceptional management capabilities in China provides customers with a wide range of solutions on the one hand, and promotes the further development of the LIB industry as a whole on the other. I am very excited about this partnership. The joint venture will provide competitive high-performance separators for LIBs in China for energy storage and mobility applications. Combining the strengths of both companies will enable new solutions to global environmental and energy challenges.”

- Lie Shi

“With this joint venture, we are now seizing the huge opportunity in the energy storage market with dry separators, just as SEMCORP has seized the opportunity in the e‑mobility market with wet separators,” added Chairman and CEO Paul Xiaoming Lee.

“Celgard’s cutting-edge technology and know-how combined with SEM-CORP’s operational experience in China, both in mass production of high-quality separators and cost competitiveness, will make this joint venture with Polypore a breakthrough supplier of dry process separators,” Lee continues.