Keeping a precise overview of the energy consumption and maintenance status of their machinery, detecting losses at an early stage and taking appropriate measures to achieve savings or avoid peak loads — manufacturing companies face precisely this challenge. SMC, the specialist for pneumatic and electric automation, and elunic, a strategy consultant and software integrator for Industry 4.0 applications, will be showing a jointly developed solution for this at this year’s SPS 2021 trade fair.

Energy losses in pneumatic systems are not only a cost factor, but against the backdrop of climate change, an issue that requires urgent action — not least in the wake of the EU’s Green Deal: Thus, by 2050, no more net greenhouse gases are to be released, making Europe the first climate-neutral continent. In order to support companies in optimizing their production and thus saving energy and CO2, SMC Deutschland GmbH and elunic AG have intensified their cooperation in the field of maintenance and repair management. The two partners will present a market-ready solution at the SMC booth 365 in Hall 3 and at the elunic booth 335, Hall 6 at the smart production solutions (SPS) trade fair in Nuremberg from November 23 to 25, 2021.

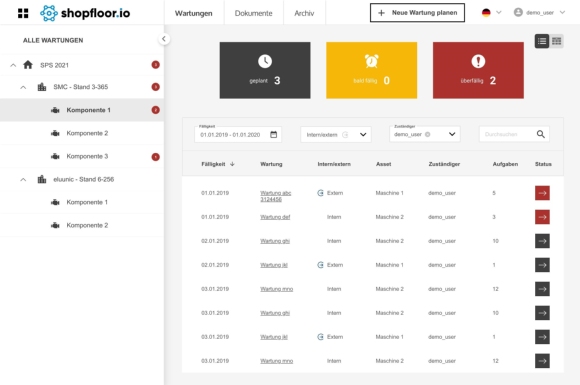

The new solution extends the “EnergyTransparency@SMC” service with the function of the shopfloor.io maintenance manager from elunic. This provides users with holistic monitoring of the energy data of their pneumatic systems as well as documentation and display of all necessary maintenance steps. For precise measurement of pressure and flow values, SMC provides “EnergieTransparenz@SMC”, a compact module designed according to the plug-and-use principle, which sends the measured values to an IoT platform from SMC every minute. The shopfloor.io maintenance manager from elunic is integrated directly into this to obtain the energy data and thus create and operate maintenance plans and tasks individually for each machine or individual measuring points. Thanks to the comprehensive documentation, the system makes it possible to track changes to machines even months to years later. Technical managers thus not only gain a precise overview of when and how defects were rectified in the past, but also the ability to extend the service life of machines through pinpoint maintenance.

The new solution offers users a wide range of benefits:

-Seamless documentation

‑Operation independent of end devices

‑Complete process in one hand — from recording to documentation

‑Facilitation of the workflow within maintenance

‑All necessary information directly at hand and time savings when searching

‑Live overview of all maintenance cycles at any time

“In the environment of digitalization and Industry 4.0, partnerships are indispensable to bundle expertise in the best possible sense. Our home is directly at the machine as well as the plant, and here our components such as sensors and actuators play a decisive role. After all, this is where the data that needs to be forwarded originates. In addition, networking of the individual data points is also very important, both of which we achieve through our “EnergyTransparency@SMC” service. Through the partnership with elunic, we are demonstrating very concretely not only the technical feasibility for innovative solutions, but also how they can be turned into real added value for customers.”

- Christian Ziegler, Head of Digital Business Development

“Through our many years of experience in Industrial IoT for machine manufacturers, we have already gained valuable insights into mechanical engineering and know the challenges faced by users there. Through the partnership, we gain even better access and receive an optimal interface for our shopfloor.io maintenance manager to the important energy data via their IoT platform,” explains Claudio Gusmini, Director IoT Solutions, elunic AG. “Both machine builders and operators benefit from the overall solution. This makes it clear what added value is created by bundling competencies — a core idea of Industrie 4.0. The basis for this is not only openness when it comes to data, but also between partners, and this is precisely what is fulfilled in the cooperation.”