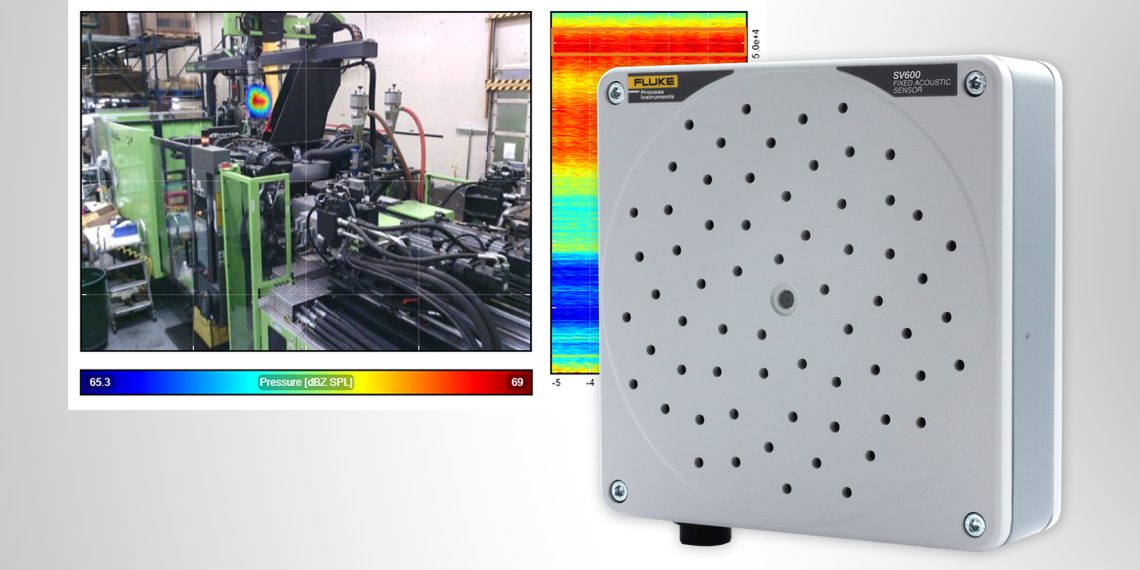

The SV600, the first acoustic camera from Fluke Process Instruments, is designed to detect gas leaks and mechanical faults and weaknesses. Changing noise characteristics of machinery and equipment are detected and reported in real time before costly and time-consuming repairs are needed. Using an array of sophisticated sound sensors, a visual camera and powerful SoundMap technology, the system generates sound images that can be used to quickly locate and assess potential fault sources. The camera allows easy integration into operations control systems.

The acoustic camera is suitable for quality control in mechanical engineering as well as for continuous monitoring of equipment such as compressors, pumps, pipes and conveyor belts, where it detects changes in noise emissions at an early stage. User-specific alarms and comprehensive remote analysis options make intervention by service personnel unnecessary in many cases. This reduces costs, not least in plant areas that are difficult to access. The innovation is also available as an accessory for mounting on the Spot mobile robot from Boston Dynamics.

This slim quadruped takes automated inspection to a new level: it can inspect places that are inaccessible to other robots, including uneven terrain, and provides users with insight into remote areas and hazardous zones. The product is available now.