E‑commerce is booming and with it warehouse automation. Flexible storage systems are also in demand in warehouses of large food chains, which require environmentally friendly, sustainable and intelligent drive concepts. The drive specialist NORD DRIVESYSTEMS knows exactly the needs of the industry and offers a variety of dynamic drive solutions that meet different applications and requirements in warehouse logistics.

The company offers customized drive solutions for warehouse logistics for an optimal compromise between investment, operating and maintenance costs. The drive units with motor efficiency class IE4 and system efficiency class IES2 achieve excellent efficiencies especially in the partial load and partial speed range. With the latest generation IE5+ permanent magnet synchronous motor, even higher energy efficiency can be achieved and energy consumption significantly reduced. The constant torque over a wide speed range also enables targeted variant reduction. In this way, administrative expenses can be minimized and manufacturing, logistics, storage and service processes can be streamlined.

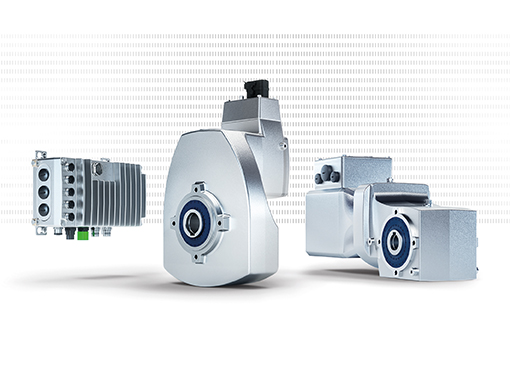

The decentralized frequency inverter

The NORDAC ON decentralized frequency inverter was developed specifically for the requirements of horizontal conveyor technology in the warehouse area and the NORDAC ON+ variant for interaction with the new IE5+ synchronous motor. It is characterized by an integrated Ethernet interface, its ease of maintenance due to complete pluggability, and extremely compact design, and offers an economical as well as intelligent plug-and-play solution for IIoT environments. The compact, smart frequency inverter for decentralized use can be mounted directly on the gearmotor. It covers smaller power ranges up to 2.2 kW and offers an energy-saving function in the partial load range. The integrated Ethernet interface reduces the effort required for integration into modern automation systems: Whether ProfiNET, EtherNET IP or EtherCAT, the desired protocol can be easily set via parameters.

More efficiency in conveyor technology

The NORDAC FLEX SK 205E series is also ideal for applications in warehouse logistics. The compact, decentralized, and energy-efficient frequency inverter offers a wide power range up to 22 kW and enables energy savings across the entire load range. The inverter can be used to control standard asynchronous motors, high-efficiency synchronous motors and brake motors. It can be installed close to the drive in the field or mounted on the motor.

Power and data cables can be connected in a plug-in manner. The decentralized system allows short motor and encoder cables as well as short supply cables to sensors. Encoder feedbacks can be implemented, for example, for position-controlled transport systems. Since the NORDAC FLEX SK 205E offers a high overload capacity, dynamic movements with short start and stop times or cycle operation are also possible. The integrated control enables high accuracy in synchronous and positioning applications.

Modular system for optimum drive solutions

Overall, the company impresses with a wide range of products for the warehouse sector, including both established basic and high-efficiency products. The user benefits from customized and reliable drive solutions that ensure optimum system availability. The modular drive system thus enables an optimum compromise between investment, operating and maintenance costs.