The Institution of Chemical Engineers (IChemE) has today formally launched its Knowledge Hub, a virtual library for process engineers to access thousands of resources developed across IChemE.

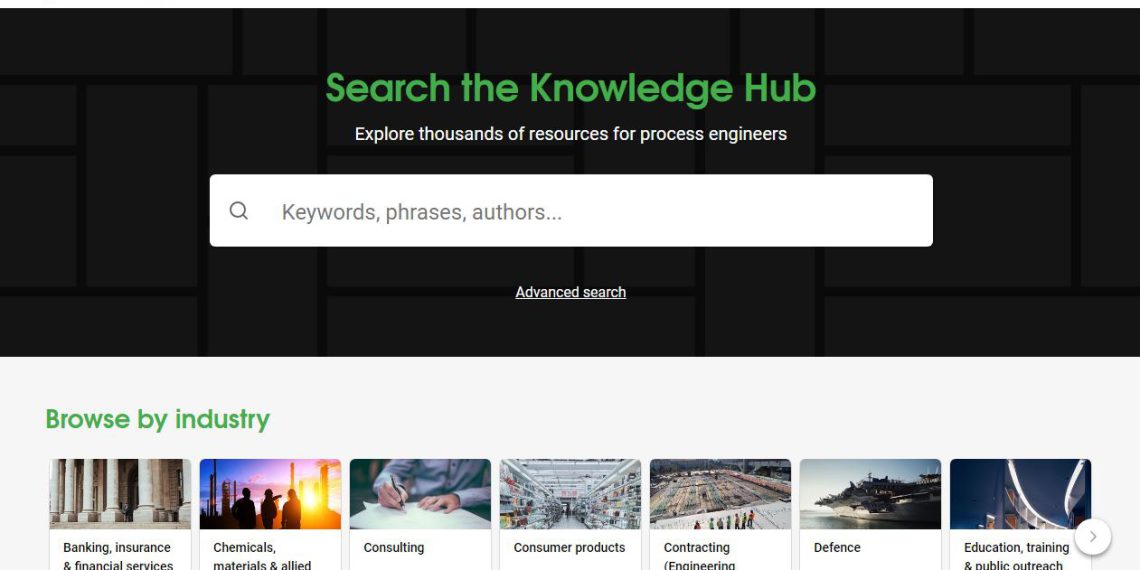

The Knowledge Hub brings together over 9,000 pieces of technical content in one central location, accessible through a single searchable index.

Featuring information from a broad range of sources, content on the Knowledge Hub includes historic journal papers, incident reports, good practice guides from the IChemE Safety Centre as well as articles from The Chemical Engineer and the Loss Prevention Bulletin.

Also included are selected online training courses, proceedings from previous Hazards events as well as IChemE submissions to policy consultations.

Viewers can browse by industry, topic, author or date, or alternatively use the handy search bar. With the comprehensive search functionality, this extensive library of IChemE technical information is now available at the click of a button.

Jarka Glassey, Vice President Learned Society said:

“IChemE has historically produced and continues to produce an exceptional amount of technical content helping to inform, advise and provide guidance to chemical and process engineers around the world. The Knowledge Hub is a fantastic resource that enables members and others involved in the chemical engineering profession to access the full extent of this information with just a few clicks of the mouse.

“Over time we will continue to add more and more content to the Knowledge Hub, ensuring that all of IChemE’s technical information and guidance is easily accessible in one place.”