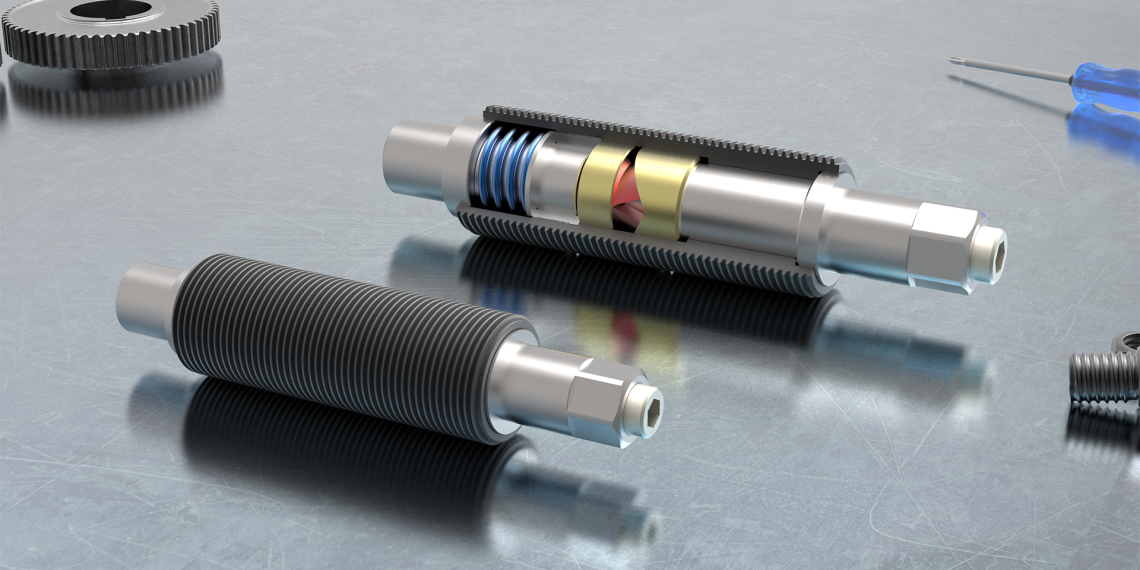

Workpieces up to approx. 50cm are usually mechanically and manually clamped with three- or four-jaw chucks, or automatically by pneumatic or hydraulic. If, however, the workpieces to be machined are larger, then planar disks are used. They also hold much larger parts safely on site with jaw boxes and tensioning spindles. As a user, you have the choice between 7 standard thread sizes from TR 50 to TR 200, with which, due to the proven principle of force multiplication by means of wedge clamping system, clamping forces of up to 500 kN can be achieved. In addition, self-locking is achieved in each tensioning position as well as a high degree of stiffness. The power clamping spindles are equipped with an internal switchover to switch between external and internal clamping. The MSP / MSPD power clamping spindles from Jakob Antriebstechnik convince by their very high clamping forces, a large clamping range and easy operation and assembly. This ensures maximum operational safety.

In order to guarantee this permanently, Jakob recommends (depending on the frequency of the clamping cycles) a regular inspection of the spindles once or twice a year. The Jakob force measuring systems, such as the hydraulic, autarkic force transducer HMD, are particularly simple. The intelligent clamping claw FMS even allows a constant clamping force control during the machining of the workpieces. The determined data can be transmitted wirelessly directly to a handheld display device or PC. If the clamping forces deviate from the stated nominal values by approx. 25% — 30%, an overhaul is recommended. Maintenance can be carried out directly. Alternatively, the company also offers training courses to certify participants as operating or maintenance personnel. This means that installation and maintenance can be carried out in the company’s own operation in the future.