At Greenplast in Milan, Italy, May 3–6, 2022, Hall 14, Booth 31, Maag Group will show integrated solutions for polymer processing in the recycling sector, specifically the ERF high-performance melt filter from Ettinger.

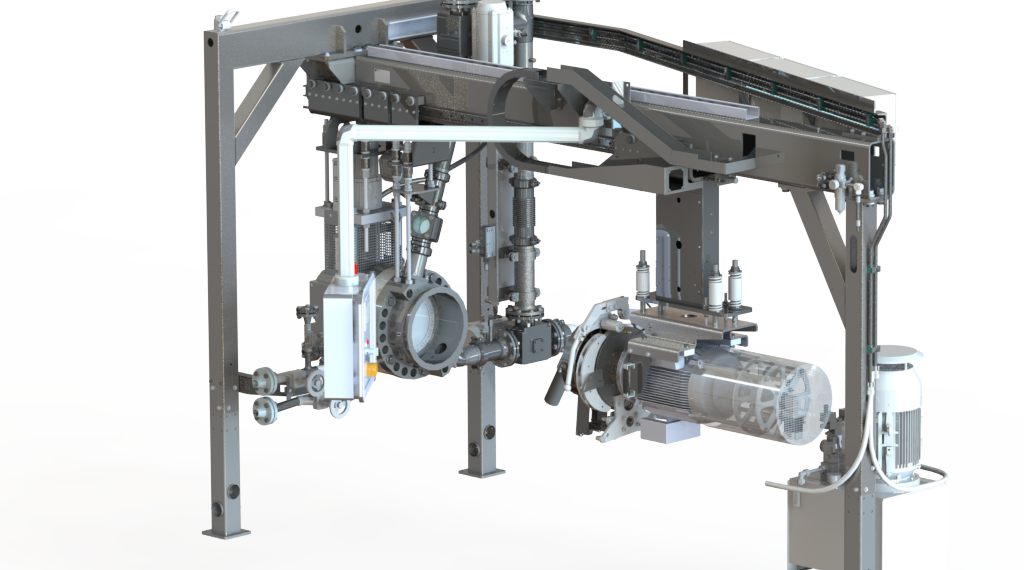

This high-performance melt filter is used to filter highly contaminated polymer melts. The filter is self-cleaning with a rotating perforated drum through which melt continuously flows from the outside to the inside. A scraper removes impurities remaining on the filter surface and feeds them to the discharge system. This allows the filter to be used fully automatically and without interruption for extended periods of time without the need for replacement. Advantages: Reliable melt filtration, extremely low melt losses, good mixing for a homogeneous melt.

PEARLO 350 EAC with liquid heated die plate for high throughputs

This underwater pelletizing system is specifically designed for high throughputs, e.g. production of 18,000 kg virgin polymer per hour. The unique knife design, together with optimal water and material flow conditions in the cutting chamber, delivers not only ideal, uniform cooling effects, but also excellent pellet quality. Another innovation is the knife infeed system, which allows axial movement of the cutting shaft for precise knife infeed as well as knife grinding even during operation. Costs can be reduced through increased line availability and longer product runs.

Innovative strand pelletizing: advantages of the PRIMO Plus Flex

Shortest unguided section combined with increased rotor diameter delivers not only more torque but also top-quality pellets.

Throughputs up to 5,000 kg/h

Profitable production thanks to very high machine availability due to wear-resistant cutting tools

For applications such as pelletizing of base polymers, recycling products, processing of highly filled compounds or ETPs into different pellet lengths, from micropellets to LFT, the product is the first choice for a reliable dry-cut strand pelletizing process.

All extrex gear pumps with the new x6 class design have been completely redesigned technically and feature redesigned components, from the shafts to the bearings and seals. The interaction between the components has also been optimized. Specially developed low-compression gear technology enables very high pressures with a low shear gradient. This enables even higher product quality and volumetric efficiency, as well as manufacturing consistency and reliability.

“Another brand first is Maag Brain. We are pleased to present this autonomous monitoring system, which marks another step towards Industry 4.0 and the Internet of Things (IoT). The system is designed to monitor pumps and ensure their maximum efficiency during operation.”

- Claudio Bonafede, General Manager