Safe and accurate transmission of torques is essential for precision drives of cross cutters. This is ensured by the use of steel bellows couplings with force-fitted shaft-hub connection.

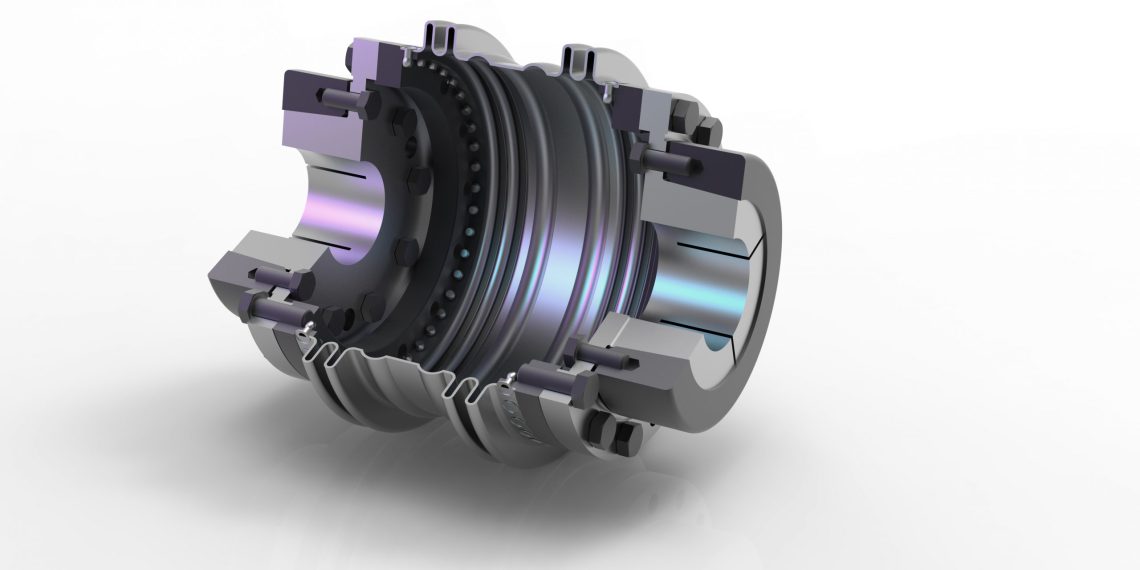

The metal bellows couplings of the KXL series from Jakob Antriebstechnik were designed for medium and large drives up to a maximum of 65,000 Nm. A special design feature is the three-piece design with a flexible bellows package as an intermediate piece. This removable intermediate piece, consisting of an optimized, torsionally stiff stainless steel bellows with 2 bellows shafts per side and a variable length intermediate pipe, is frictionally connected (screws ISO 4017 / 10.9) with the two hubs. This results in a considerable ease of assembly, as e.g. can be omitted in the maintenance or service case a costly disassembly of the heavy drive or driven units. The designer has several hub variants available for the specific application. The extremely favorable moment of inertia and the rotationally symmetric design ensure good dynamic performance. The KXL couplings are particularly suitable for precise drives, such as for printing presses, cross cutters, main spindle drives, transfer axes or transmission connections. A media transport or a parallel drive train through the coupling interior is basically possible. The connection to the shafts can be done either as a conical clamping ring hub or as a flange hub.

Hub Type A

Frictional, backlash-free conical clamping ring connection — outside – bellows package radially freely removable. For the overall length “L4”, the axial lengthening of the bellows package of 4 mm is already taken into consideration during assembly.

Hub type B

Frictional, backlash-free conical clamping ring connection — internal bellows package radial NOT freely removable.

Hub Type F / G

Mounting flange according to ISO 9409 or customer specification — centering outside or inside. Dimensions of flange hub F and G of L13, L19 and D6, D9, D10, D11, D12 according to customer specifications.

Hub Type A / B

Frictional, backlash-free conical clamping ring connection — outside / inside. Bellows package radially NOT freely expandable