Succinic acid serves as an important starting material for chemicals in pharmaceuticals and cosmetics , but it is also useful as a building block for biodegradable plastics. It is currently obtained mainly from petro-based processes. Researchers at the Straubing campus of the Technical University of Munich (TUM) are using the marine bacterium Vibrio natriegens as a biocatalyst. This could enable succinic acid to be produced from renewable raw materials in sustainable production processes.

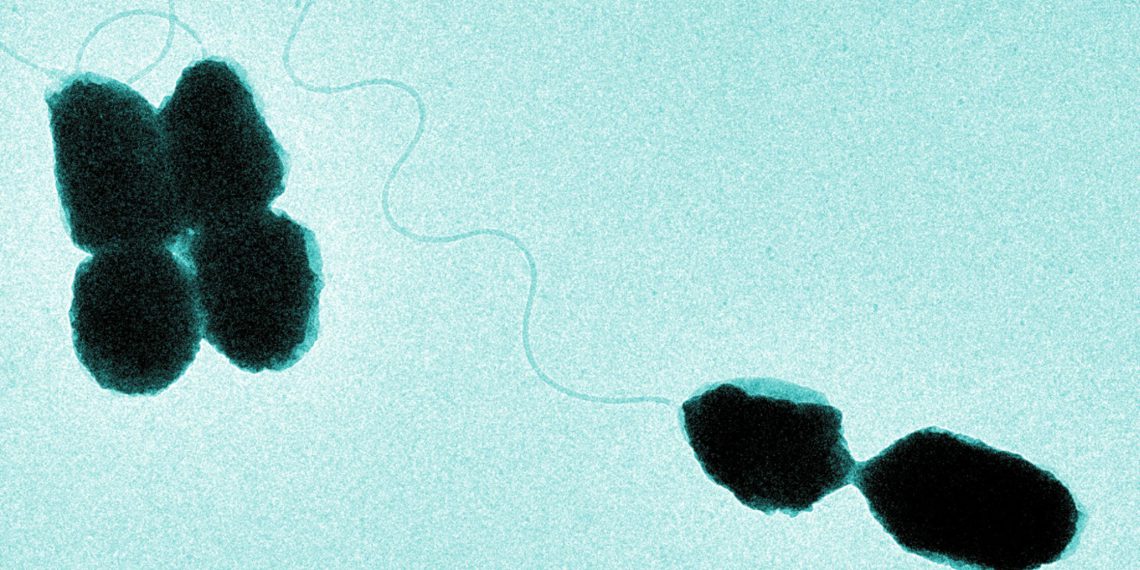

The marine bacterium Vibrio natriegens is characterized by extremely rapid growth. It is the fastest-growing, non-disease-causing organism known to date. This is accompanied by its ability to take up substrates — the starting materials for catalysis — very quickly.

“We are working at full speed to establish Vibrio natriegens in biotechnology.”

- Bastian Blombach, Professor of Microbial Biotechnology

Prof. Blombach’s team at the TUM Campus Straubing for Biotechnology and Sustainability is working on using this marine bacterium to make production processes more time-efficient and thus more resource-efficient, as well as to reduce the required size of biotechnological plants.

Marine bacterium helps in the production of succinic acid

The researchers have now been able to demonstrate the potential of this marine bacterium using succinic acid as an example. Succinic acid is organic and occurs in fossil resins such as amber or also in lignite. In nature, the acid is found, for example, in unripe grapes, rhubarb or tomatoes.

In the metabolism of all organisms, succinate, the salt of succinic acid, occurs as an intermediate in the breakdown of glucose. The natural occurrence of succinic acid in metabolism is now being exploited in biotechnology to have it produced specifically by microorganisms such as the marine bacterium used by the researchers. To do this, an understanding of the metabolic performance of microbial platforms such as Vibrio natriegens is essential.

Potential for industrial biotechnology

Prof. Blombach’s team uses metabolic engineering methods to develop such novel microbial systems for industrial biotechnology. Modern genetic engineering methods can then be used to create customized cell factories.

“We filled plastic tubes with a salt solution in which Vibrio natriegens is comfortable, added glucose and sealed the whole thing airtight. In the absence of oxygen, the bacteria then converted the sugar and CO2 dissolved in the medium to succinic acid. This process was completed after about two to three hours.”

- Dr. Felix Thoma, scientist at the Chair of Microbial Biotechnology

In the further course of the study, the researchers conducted the experiments in the bioreactor. There, they were able to additionally control the pH value, because the formation of the acid would otherwise make it inhospitable over time. They were also able to “refeed” sufficient substrates.

A bacterium on its way to becoming an important process partner

Succinic acid is among the twelve key products that could be produced biotechnologically in the future to compete with a petrochemical presentation. “Only two years of development work with the marine bacterium have resulted in comparable performance characteristics to other systems after 15 to 20 years. This makes the marine bacterium a potent new player in industrial biotechnology,” Thoma says.

Through targeted genetic modification, the research team has succeeded in optimizing the metabolism of this bacterium so that glucose is efficiently converted into succinic acid — and with very high productivity. “On the way to an industrially relevant process, a lot still needs to be done in terms of process control,” says Prof. Blombach. Now the research team is focusing on process development with Vibrio natriegens and the usability of renewable raw materials and waste streams that do not compete with the food industry.