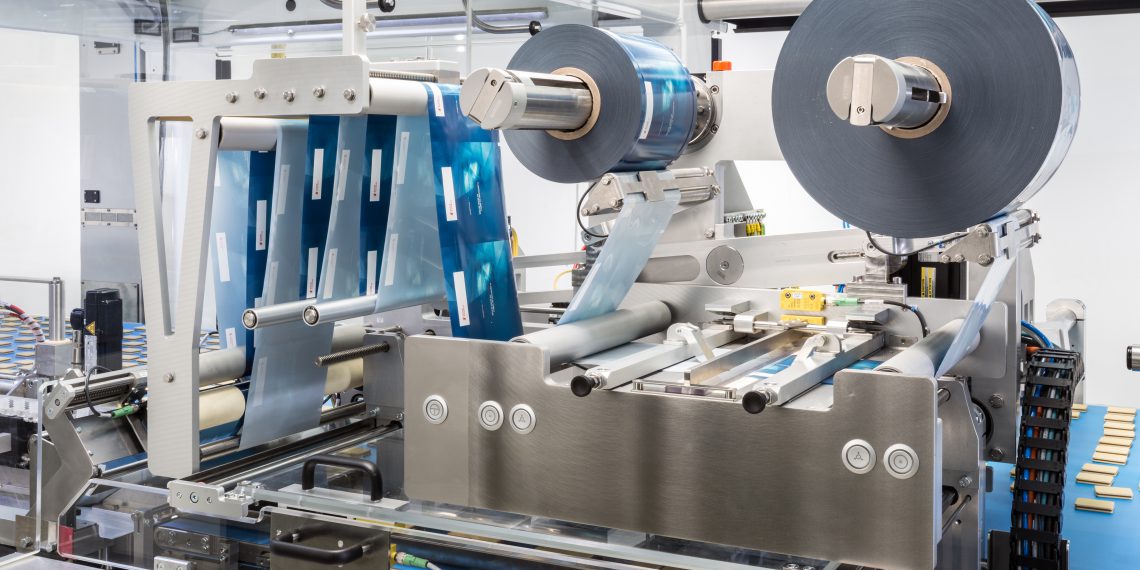

Schubert offers the latest model of its Flowmodul flow-wrapping component. With a targeted focus on the user, the company has significantly improved both machine accessibility and ergonomics for maintenance and cleaning work. Since its market launch in 2016, the Flowmodul has successfully established itself on the market: over 36 flow-wrapping components have already been sold worldwide.

With the Flowmodul, food producers greatly benefit from the integration of primary and secondary packaging processes. The flow-wrapping component is fully integrated into a TLM picker line and can package both bare products such as sweets, or snacks in trays. Manufacturers benefit from a flexible, high-performance machine with a small footprint, which can very efficiently handle small batches, short product lifecycles and a high level of product variety. Moreover, manufacturers can count on system efficiency of 99 per cent and more. The standard system component is equipped with fully automatic carrier changing utilising exchangeable cassettes for further formats, plus format conversion is completed within one to ten minutes. Furthermore, the ability to install two Flowmoduls per machine can double production output.

“As planned, the Flowmodul has become an important growth factor for our group of companies,” highlights Johannes Schubert, grandson of the company founder and, since January 2017, the Flowmodul’s product manager. Currently, flow-wrapping technology is used to package a wide range of products, such as chocolate bars, biscuits, cakes, chocolate figures, yoghurt cups, confectionery waffles, puff pastries and ice cream.

New sealing technology for temperature-sensitive products

The Flowmodul’s most recent development allows customers to eliminate the cold seal film for the first time ever, even for temperature-sensitive products. Switching from cold to heat seal technology can result in material cost savings of up to 17 per cent. “The key lies in constant sealing times at variable chain speeds. Here we will be setting new dimensions in the heat-sealable film’s control range,” explains Johannes Schubert. The first prototype successfully completed the test phase and will go into production in May 2018.