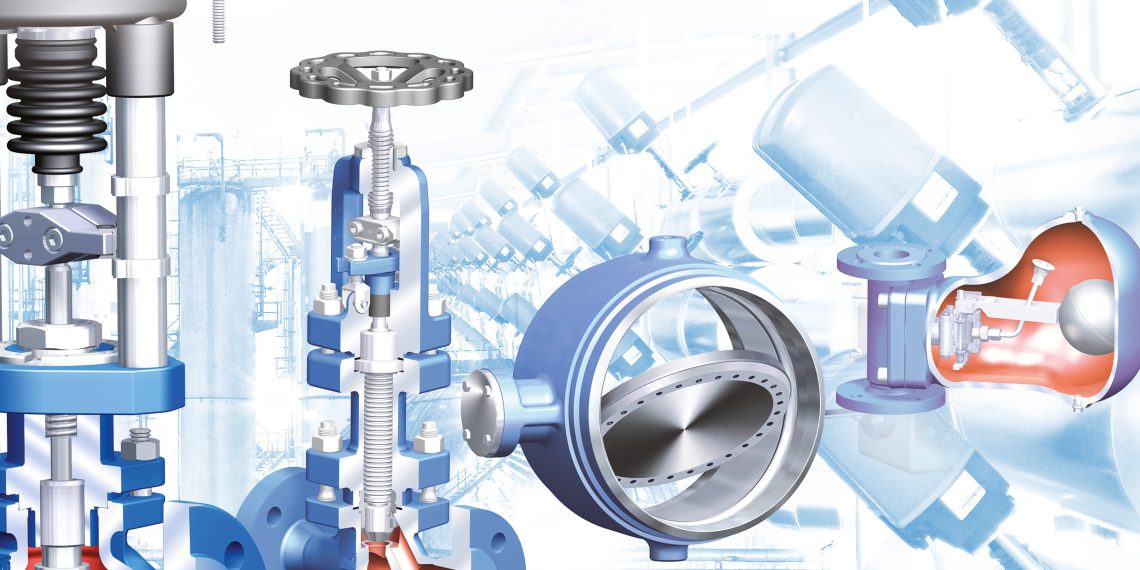

20,000 products in more than 200,000 variants! A comprehensive, high-performance range of valves for the process industry – built to comply with the highest quality standards according to DIN ISO 9001–2015. Ari-Armaturen will be showcasing an impressive variety of innovative products at Achema 2018 (Hall 8.0, Stand B45).

The butt weld end version of Zetrix, the metallic sealing, triple offset premium process valve, is a new addition to the Ari range. It is available in sizes DN 80 to DN 600 for PN 6 to PN 40 (class 150/300). Also new from the company: the fully lugged, wafer flange version is now additionally offered in DN 80 to 600 for PN 63/100 (class 600). For several years, this sophisticated range of process valves with metallic sealing and a self-aligning sealing ring has been rounded off with a double flanged version. Zetrix valves combine extreme reliability and durability. All models have a stellited seat and are firesafe tested with bidirectional gas-tight shut-off and zero leakage according to EN 12266–1 and API 598.

Everything is possible with the new Stevi Vario – the variable, compact control valve which impresses with its enormous diversity. In particular, the changeable, variable trim and the different actuator designs provide users with incredible flexibility. The Stevi Pro high-performance control valve for professional control, especially in critical applications, further extends the range. The stainless steel variant can now also be supplied by the company with a stainless steel bellows. With its optimised characteristic quality, high precision and performance are guaranteed. And thanks to the blow-out proof stem and shaft guided plug – as well as a two-ply bellows seal on request – the Stevi Pro is safe even in harsh industrial environments.

The bellows valve range, already very versatile, has likewise been expanded. For the first time, the firm can now offer the process industry Faba Supra MD bellows valves for PN 63 to PN 160. When fitted with a balancing plug, these valves are even safer to use (optional from DN 65). They are reliably tight, even at high pressures, owing to the bellows seal, serrated seal and stellited marginal plug (ideal hardness gradient: Stellite 6 / Stellite 21).

The safety valves product group has been extended yet again. In future, customers can now optionally order any Safe valve in stainless steel – up to size DN 250 including a stainless steel bellows. The bellows not only provides backpressure compensation; it also seals and protects the spring chamber and the guides. The two-fold safety due to the separate balanced piston, which acts redundantly with the bellows and is supplied as a standard feature at no extra cost, is a another decisive advantage! Increased safety is possible on request in the form of two combinations: Safe Combi‑C (change-over valves) and Safe Combi‑R (rupture discs).

The large Cona family of steam traps has acquired new members too: in addition to the established range of bimetallic, ball float, diaphragm capsule and thermodynamic traps, the company can in future also supply a compact Cona S ball float steam trap for higher condensate volumes as well as the familiar Conlift condensate pump – now also in stainless steel or with a cast steel body.

If the volume of condensate exceeds 10,000 kg/h and the pressure conditions are problematic, with differential pressures up to 32 bar, Cona S makes a good alternative. With its standard face-to-face dimensions, 13, 21 and 32 bar differential pressures and all the usual approvals for the international markets, it is a highly versatile product for (large-scale) plant manufacturing. The robust lever and ball design is in keeping with the firm’s strong commitment to quality and the foundation for a long life.

The process industry can profit from more product diversity when it comes to condensate pumps. The slightly modified design means that fewer dead spaces have to be filled with steam, so that less motive steam is required. The cast steel variant is moreover lighter and features a new controller for 14 bar differential pressure. The new Conlift design in corrosion-resistant, long-lasting stainless steel opens up additional applications in the process industry.

This extremely versatile and sophisticated range for the process industry is rounded off with various systems – such as PREsys (for pressure reduction), CORsys (for condensate recovery and return) or ENCOsys (for heat exchange).

Speed, expertise and dependability, with all products built to comply with the highest quality standards according to DIN ISO 9001 – this is the promise the company makes to its customers! Finally, myValve – the valve sizing program – is an intuitive software package providing access to all important information on the entire portfolio as well as all essential sizing calculations whenever they are needed.

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more