NTT Communications Corporation (NTT Com) and Yokogawa Electric Corporation have contractually agreed to develop and provide a shared cloud service for operational technology (OT). This service is intended to drive digital transformation (DX) in the manufacturing industry by combining the respective strengths of Yokogawa and NTT Com in OT and IT.

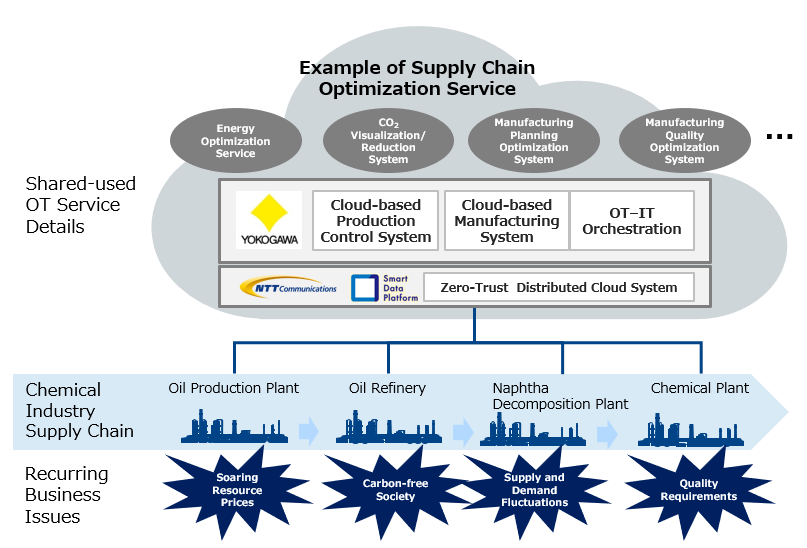

The plan is to adapt production control systems and manufacturing control systems for use in cloud-based services and then develop them further by creating a shared OT cloud service.

Background

Recently, the manufacturing industry has not only had to deal with rising raw material prices, supply and demand fluctuations, and the development of high-quality products, but also has to respond quickly to changes in a diversifying business environment. However, manufacturing plants and their control systems are built in on-premises environments where availability and robustness are paramount to ensure trouble-free operation. Thus, immediate system-related changes pose a major challenge. These problems can only be overcome by highly flexible system configuration.

Moving systems to the cloud has long been common practice in the IT sector. The two companies will apply this strategy to OT and deploy a shared OT cloud service to optimize manufacturing flexibility and data utilization.

Adapting production control systems (PCS) and manufacturing execution systems (MES) for cloud services

Yokogawa already offers services such as Yokogawa Cloud that analyze plant data in the cloud and streamline maintenance operations. Now, specific OT systems are to be adapted for use with NTT Com’s Smart Data Platform. This data platform provides a one-stop solution for all functions required to effectively use enterprise data and ensure a highly secure environment, and enables tasks such as system renewal, function expansion, and control setting changes to be completed quickly.

Develop and deploy a shared OT cloud service.

By adding OT IT orchestration capabilities to the cloud services for production control and manufacturing execution systems, the two companies will develop and deploy a shared OT cloud service. This will not only enable rapid system upgrades and feature enhancements as needed, but also seamless data exchange between users and optimization of overall supply chains at the manufacturer.

For example, by analyzing data, manufacturing techniques can be identified that can reduce carbon dioxide (CO2) emissions not only from individual companies, but also across entire supply chains.

Expanding the partner network

The two companies are looking to attract more partners who can functionally extend the shared OT Cloud service to increase the number of users. “This partnership lays the foundation for valuable collaboration and enables the implementation of the ‘system of systems’ concept we are striving for. We will provide services that bring together the IT and OT of both companies, allowing us to integrate numerous systems and achieve overall optimization that contributes to solving urgent social problems.” Hitoshi Nara, President and CEO of Yokogawa Electric Corporation

“We will meet the stringent requirements of cloud-based plant control systems in terms of real-time performance, availability and security by leveraging our distributed edge and center cloud systems as well as our low-latency networks. Through collaboration between the two companies, we will optimize the entire supply chain in the manufacturing sector and create an industrial model that supports the shift to a sustainable society.”

- Toru Maruoka, President and CEO

Future plans

Under this alliance, the two companies will launch an experiment in February 2022 to demonstrate the migration of production control and manufacturing control systems to a cloud service. The plan is to launch the cloud service by the end of fiscal 2022.