As diaphragm pumps are oil-free, they are suitable for all work and numerous applications where a clean, dry vacuum is required. Examples include laboratories, analytics, leak detection and research & development. With the MVP 030–3 C DC, Pfeiffer Vacuum has brought a corrosive gas version of the diaphragm pumps onto the market. This version features a gas ballast valve and good chemical and condensate compatibility. The choice of materials ensures robustness in a wide range of processes.

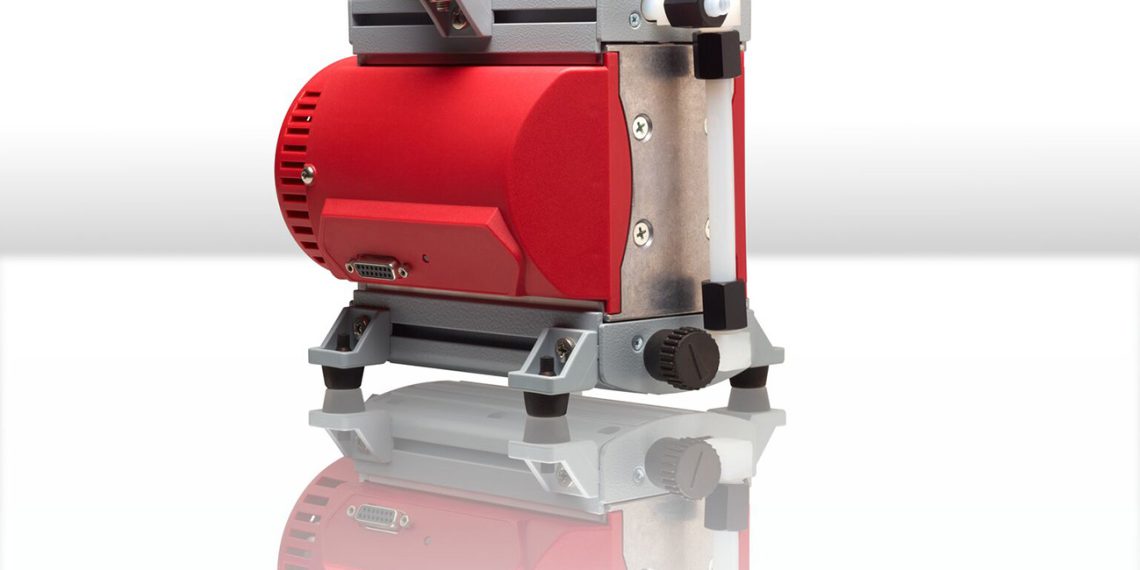

Diaphragm pumps not only do their job reliably, but also quietly and with low vibration. The noise level is below 45 dB(A). Due to their compact design and low weight, they fit into small analysis systems, mass spectrometers and turbo pumping stations. Due to the mutual controllability, intelligent operating states can be parameterised. This reduces power consumption and wear. Diaphragm pump and turbopump can be controlled via a single Pfeiffer Vacuum operating unit and are supplied with power via a common cable. This results in less cabling and lower costs.

The brushless DC drive system allows the speed to be adapted to the requirements of the respective application. In automatic boost mode, the pump starts at overspeed. This can shorten the ramp-up times of the connected systems, enabling users to commission the systems more quickly. The speed is reduced as soon as a certain vacuum is reached or a certain time interval has elapsed. This brings more efficiency and long maintenance intervals.

In addition, the diaphragm pump series achieves high energy efficiency through standby and possible interval operation together with turbopumps. The 24 V DC power supply means that the electrical design and associated safety measures are less complex, which further reduces costs. The three-stage MVP 030–3 C DC is equipped with a manual gas ballast valve. Possible condensate build-up in the diaphragm pump can be prevented by opening the gas ballast valve. This leads to higher process reliability and a longer service life. Added to this is the uncomplicated maintenance of the diaphragm pump. Both the diaphragm and the valves can be replaced easily and in a time-saving manner. The DC drive ensures that the pump can be used worldwide.