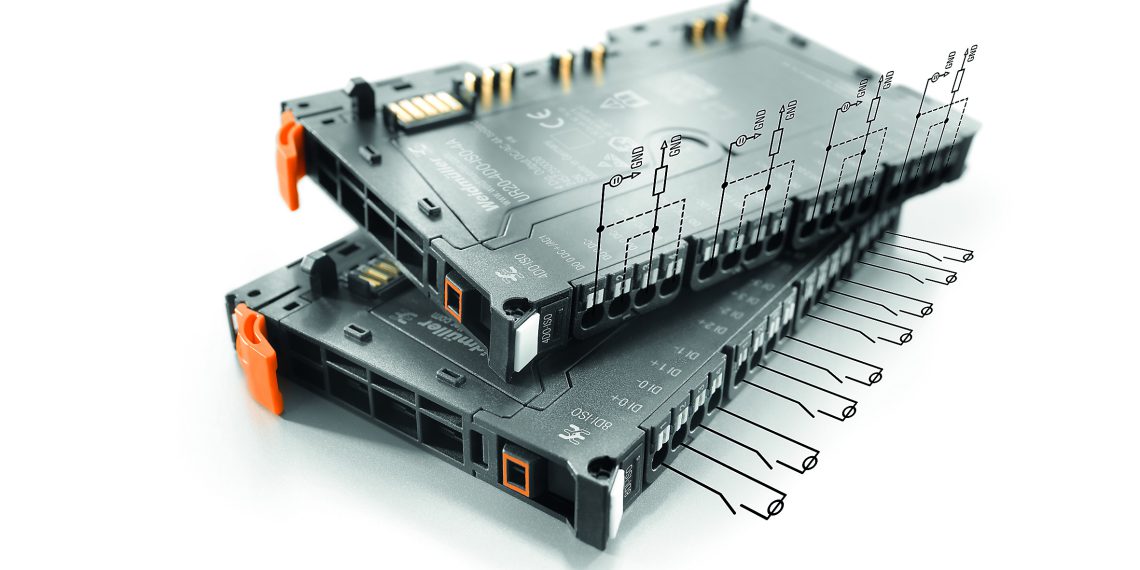

The u‑remote family from Weidmüller is established on the market and now includes the I/O modules “UR20-8DI-ISO-2W” and “UR20-4DO-ISO-4A”, which receive galvanically isolated input and output signals. u‑remote is an element of the u‑mation automation and digitalisation portfolio.

Interferences are common on decentralised machines and production lines, process plants as well as marine and offshore applications, due to ground loops or line-induced field influences. The reasons for this are long cable distances and complex networks. In these kinds of applications, it is difficult to avoid connecting shieldings several times, therefore cable loops are formed. Even if all interfering influences were minimised during commissioning, these occur at the latest when carrying out upcoming extensions or repairs. If one of the shields is damaged, a shield connection is not completely planar or oxidised, the induced interference fields immediately affect the signal and data transmission. There are also an increasing number of internal sources of interference, such as frequency convertors and lighting equipment. With galvanically isolated input and output signals, these kinds of interferences can be effectively limited or even completely avoided. Ideally, they will remain below the limit value therefore will not impact upon the system’s function. However, if interferences do occur, the source of the error is easy to find. For these kinds of applications, Weidmüller has developed the new “UR20-8DI-ISO-2W” and “UR20-4DO-ISO-4A” I/O modules. Thanks to the galvanic isolation of min. 500 V between the channels and the system, this enables uninterrupted operation, even in loaded applications. The channels are protected against mutual interference and also against external disturbances.

The “UR20-8DI-ISO-2W” digital input module can receive up to eight binary control signals using two-wire technology. The “UR20-4DO-ISO-4A” digital output module enables up to four actuators to be controlled via four outputs using two-wire technology, with up to 4 A DC or 2 A AC and up to 48 V AC/DC. With both modules, there is a separate status LED on each channel, to keep the user on site informed of the operating status at all times. This provides a high output density with maximum flexibility. With just 11.5 mm width, the new modules meet the requirement for compact and space-saving automation solutions, and are thus the ideal addition to the u‑remote product family.

Weidmüller at the SPS 2019: Hall 9, Booth 351