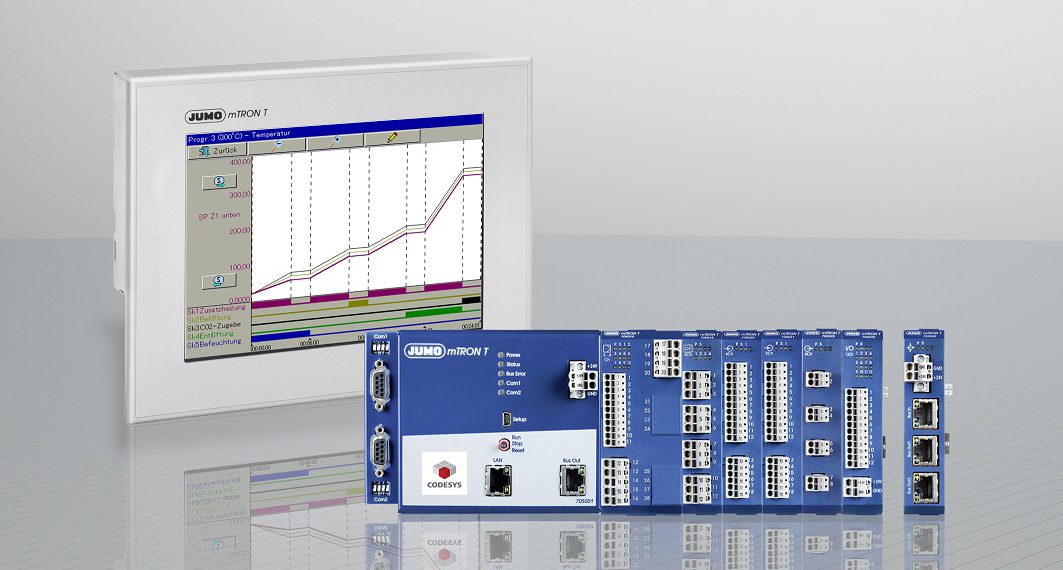

The Jumo mTron T scalable measurement, control, and automation system is currently being successfully used in a wide range of industries while simultaneously always being optimized. Numerous improvements have now been combined in the new system version 05.

For example, an option to preview the program directly in the system’s multifunction panel has been added. Previously, this was only possible in the setup program. In the new version, personalized user registration can now be performed via an interface. One such example is a RFID chip card. This option provides a simple as well as transparent registration process and protects the system from unauthorized use by third parties. A maximum of 50 users can be created and assigned to different user profiles.

In addition, the process contacts in the process steps have been expanded from 16 to 64. As a result, simple and versatile applications can be created in process engineering without knowledge of PLC programming. Additional variants of the

mTron T operating panels can be connected by updating

the Codesys runtime system.

Numerous improvements have also been made in the setup program. For example, the TAG numbers have been extended from 7 to 42 characters and the number of analog, integer, and digital variables within the central processing unit (input values for communication via fieldbus) has been increased from 64 to 128. The Modbus interface description has also been expanded. One other new feature is an import and copy function for input and output modules. Another new function is the designation for limit value monitoring functions, binary links, and for mathematical and logical functions.

Jumo at the BrauBeviale 2018: Hall 6, Stand 119

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more