Nord Drivesystems supplies individually configured drive systems in accordance with EU Directive 2014/34/EU and IEC Ex for application in potentially explosive atmospheres. The drive specialist has many years of experience with gas and dust explosion protection and for more than a decade has produced explosion protected motors which meet even the most stringent requirements. The explosion protected drive systems can be operated in category 2D or 3D dust atmospheres (Zones 21 and 22) as well as in category 2G or 3G gas atmospheres (Zones 1 and 2). A combined dust/gas explosion protection is also available.

Nord supplies application-specific drive solutions with individual configurations and equipment from its SAP-supported modular system with validated configuration processes according to ISO 9001. On the basis of customer specifications, the firm calculates individually by testing the Atex conformity and also delivers the appropriately modified type plate. If required, the maintenance intervals which are determined for the specific application can be stamped on the type plates.

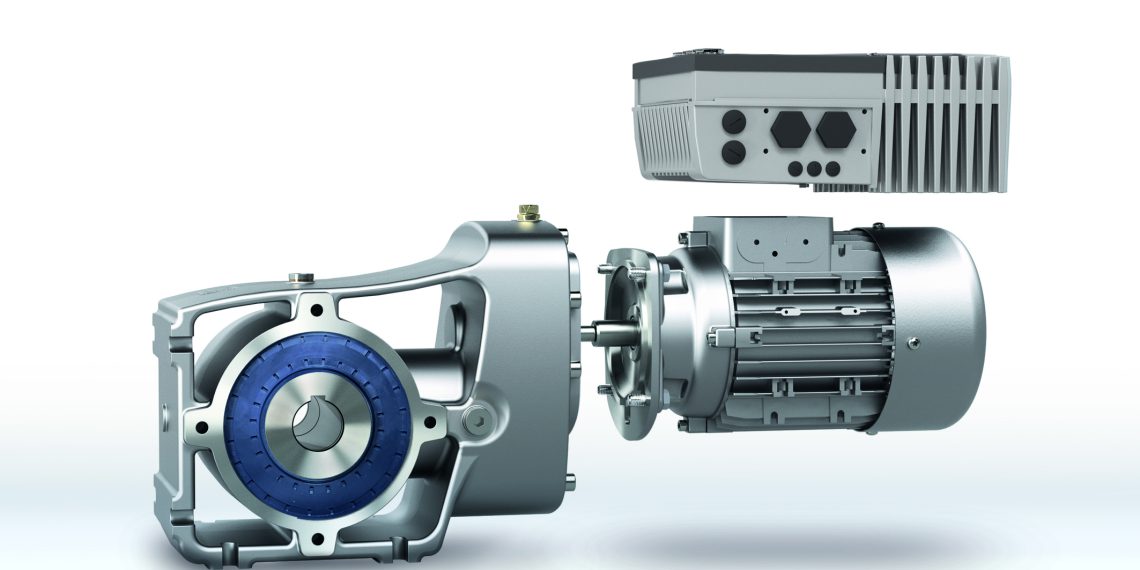

The company offers flexible drive concepts with motors which are optionally designed for use with inverters as well as the option of IEC or NEMA motor mounting. In many cases, it can be mounted directly on the gear unit for an especially compact solution. The explosion protection range includes systems for ambient temperatures up to +60 °C and is characterised by delivering world-wide with documentation in more than 20 languages.

In order to maintain the quality of production, inspection as well as the products, the company works very closely with the Physikalisch-Technische Bundesanstalt (PTB) and the Dekra Exam GmbH. All Category 2 motors have type test certification. Explosion protected drives are used in almost all industry sectors in a wide variety of applications, e.g. to drive pumps, agitators or lifting gear.

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more