Special high-speed test benches are used to test bearings. In these tests, the effects of different lubricants on the sliding properties of the bearings in the endurance test are checked. The structural design of such a test rig must meet different requirements. The drive is subject to special conditions. In addition to a lateral force-free storage, the coupling is a not to be underestimated component. Essential features in this case are the absolute torsional rigidity, the good damping properties and, of course, the precise and almost powerless compensation of all offset errors between the shaft ends.

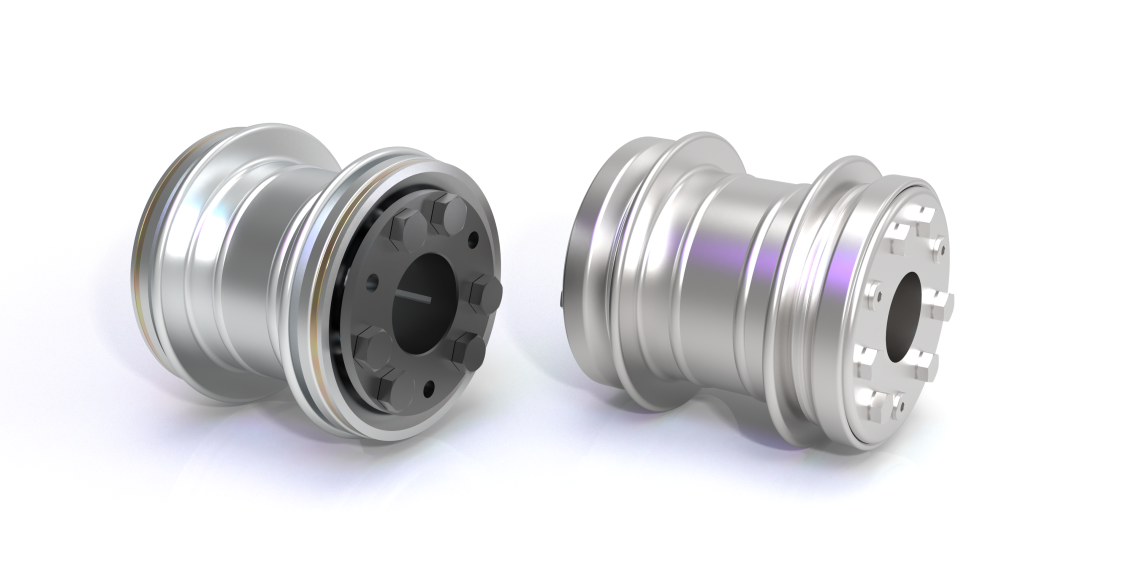

For such applications, torsionally rigid flexible couplings are generally ideal. The thin metal bellows have in addition to the balancing, also vibration-damping properties. The high flexibility of Jakob’s KSS couplings with its 2‑wave bellows and straight adapter and the easy mounting option of the coupling through the use of cone bushings as a shaft-hub connection guarantee a safe transmission of all forces and torques, even with small shaft diameters and torques without additional feather key. The rotationally symmetric design ensures excellent, dynamic operating behavior, even at very high speeds. The high torsional rigidity and the very low restoring forces with shaft misalignment as well as the low moment of inertia characterize the coupling type. Torques from 25 to 2500 Nm are possible. Highest quality in processing and the materials used make the KSS couplings a reliable and economical component. It is used, in addition to the test stands as a highlighted example, also particularly often in servos and actuators.