A reliable and low-maintenance alternative to conventional gas chromatography (GC) evaporator systems are analytical systems based on Raman spectroscopy, which are used in custody transfer transactions to measure the composition and energy content of liquefied natural gas. This is the conclusion of a study conducted over several years by the European Gas Research Group (GERG) comparing different methods. GERG represents 33 member companies and organizations from 15 countries.

“Raman spectroscopy is just becoming of increasing interest worldwide when it comes to determining the composition of LNG. As an analytical technique, Raman is robust, efficient and at the same time economical. When it comes to critical, custody transfer transactions, companies can rely on our Raman instruments to ensure that their LNG measurements are correct and accurate. At the same time, maintenance requirements are significantly reduced.”

- John Schnake, Managing Director and Corporate Director Process Analyzer

Contributing to the global energy transition

Global efforts to reduce greenhouse gas emissions are ensuring that demand for liquefied natural gas is growing rapidly because large volumes of natural gas can be transported around the world so efficiently. In the process chain, the custody transfer in sea and land transportation is always a critical step. At each of the contractually defined handover points, fast and reliable measurement of the composition of liquefied natural gas is crucial. Even the smallest differences in calorific value can change the value of a cargo by a few hundred thousand euros.

Certified and validated LNG data

The goal of the evaluation project was to validate the performance of Raman technology in reliably, correctly, and accurately determining the composition of LNG, as needed to calculate energy content during custody transfer. As part of the multi-year study, wide-ranging investigations were conducted at a transfer facility at Fluxys LNG in Zeebrugge, Belgium, during base-load operation.

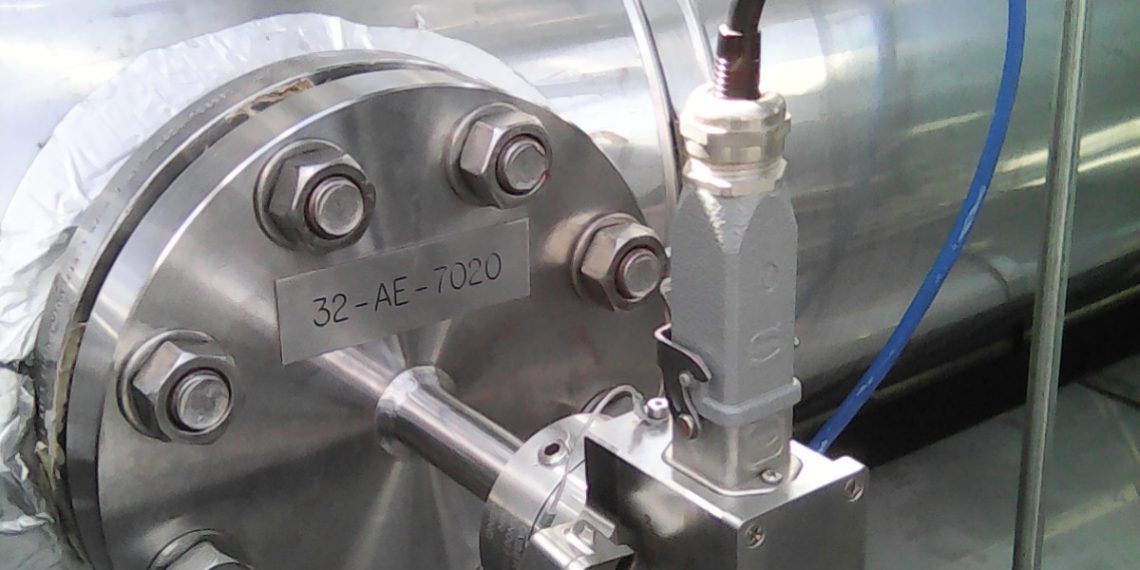

Appropriate reference samples were provided to ensure that the data met the metrological requirements for LNG applications. EffecTech, a leading provider of inspection, calibration and testing services, was responsible for this. In each case, the measurements were carried out directly in the liquid phase. The Endress+Hauser Raman system used consisted of an Rxn-41 cryogenic Raman probe connected via fiber optics to a Raman analyzer optimized for LNG.

Reliable Raman measurements with lower operating costs

The study report, entitled “Raman method for determination and measurement of LNG composition,” which has since been published, concludes that Raman analysis systems from Endress+Hauser offer comparable measurement uncertainty to traditional gas chromatography-evaporator systems, but with significantly lower operating costs and lower technical expertise requirements. Not only did the Raman system reduce the complexity of the LNG monitoring system, stabilization times after system startup were much shorter.

In addition, repeatability was better, response to process changes was faster, and the system required no maintenance throughout the assessment period. System uptime exceeded 99%. These results show how valuable the use of Endress+Hauser’s Raman measurement technology can be, for field installations at LNG baseload, satellite, and peak shaving sites, or for LNG loading stations for tankers or gas tankers.

“The results presented in the GERG study clearly demonstrate the value of our Raman analysis portfolio when it comes to custody transfer of LNG. We are very pleased about this,” explains John Schnake. “We can offer fast and reliable liquid phase measurements at these important points in the LNG process chain. Our Raman systems thus play an important role in the global energy transition that is just picking up speed.”